7

JINCHI05 REV E. 11/11/2014

de-ash before refuelling and do not let the ash level

reach the underside of the grate bars.

Solid mineral fuel produces ash, which if allowed to

build-up will stifle the airflow through the Primary

air inlets and grate. This will eventually cause the

fire to die.

With some solid mineral fuels a residue of burnt

fuel or clinker will accumulate on the grate, allow

the fire to go out periodically to remove this.

IMPORTANT!

We cannot stress firmly enough how important it is

to empty the ashpan regularly. Air passing through

the fire bed cools the grate bars. Distortion or

burning out the grate bars is nearly always caused

by ash being allowed to build up to the underside

of the grate.

E

XTENDED

B

URNING

(S

OLID

M

INERAL

F

UEL

)

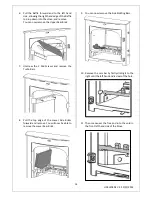

The stove can be banked up for extended burning.

When burning solid fuel, empty the ashpan. Open

air controls and let the fire burn brightly for a short

period. Refuel and close both air controls, the exact

setting required will depend on the fuel used and

the chimney draw so some practice may be

necessary. To revive the fire, open the air controls

until the fire is burning brightly de-ash if necessary

and refuel. Set air controls as required.

R

EDUCED

C

OMBUSTION

In order to reduce the combustion of the fire to a

minimum, close the primary air controls, then close

the secondary air slider by moving the handle all

the way to the left. If the controls are left in this

position, the fire will receive the minimum of air

and will die down. If you want to revive the fire it is

recommended that the Primary Air control is open

first and then open the secondary air slider.

REFUELING

Add the new fuel to the fire and open both air

controls fully to allow flames to establish on the

new fuel. Once the fire is established and the logs

are blackened, set the primary air control to its

closed position and adjust the secondary air to give

the desired heat output.

Never leave the stove unattended until you are

certain that the flames are fully established.

Avoid refuelling on to a low fire bed as this may

cause excessive smoke emission. Ensure there are

sufficient embers to ignite the new fuel rapidly.

Alternatively add some more kindling before

adding larger pieces of firewood. Do not add

firewood above the level of the tertiary air inlets on

the sides of the stove. Exceeding this amount can

result in the production of excessive smoke.

E

XTINGUISHING THE

F

IRE

In order to reduce the rate of combustion, close the

primary air lever and then the secondary air lever

by moving the handles all the way to the left. If the

controls are left in this position, the fire will be

starved of air and go out. If you want to revive the

fire it is recommended that the primary air control

is opened first, then open the secondary air slider.

WARNING!

The stove will remain

hot

for a considerable time

after the fire has been extinguished

R

ECOMMENDED

S

OLID

M

INERAL

F

UELS

Only authorised fuels may be used in UK smoke

control areas.

A list of authorised fuels can be found at:

http://uksmokecontrolareas.co.uk/fuels.php

This stove has been independently tested and

approved to burn manufactured and natural

smokeless fuels that appear in the HETAS guide.

A current list of approved fuels can be found at:

http://hetas.co.uk/public/hetas_guide.html

Approval does not cover the use of other fuels

either alone or mixed with the suitable fuels listed

above, nor does it cover instructions for the use of

other fuels.

WARNING!

Petroleum coke fuels or household waste must not

be burnt on this appliance. Do not use treated

timber.

Should any difficulties arise over fuel quality or

suitability, consult your local approved coal

merchant or:

HETAS Ltd.

Telephone 01684 278170 –

www.hetas.co.uk

Solid Fuel Association

Telephone 0845 601 4406 –

www.solidfuel.co.uk

W

OOD

L

OGS

Ensure your logs are well seasoned with a moisture

content of less than 20%.

Maximum

Length:

235mm (9 3/4”)

Summary of Contents for Chevin Inset 5 MKII

Page 24: ...24 JINCHI05 REV E 11 11 2014 ...