7

GB/CY

maximum fi lling quantity. Overfi lling the equipment may

result in damage. Reinsert the oil sealing plug (16) into

the oil fi ller opening (21).

10.6 Cleaning the intake filter (Fig. 3, 12, 13)

The intake fi lter prevents dust and dirt being drawn in.

It is essential to clean this fi lter after at least every 300

hours in service. A clogged intake fi lter will decrease

the compressor’s performance dramatically. Open the

thumb screw (E) to the remove the intake filter.

Then pull off the fi lter cover (C). Now you can remove

the air fi lter (F) and the fi lter housing (D). Carefully tap

out the air fi lter, fi lter cover and fi lter housing. Then

blow out these parts with compressed air (approx. 3 bar)

and reinstall in reverse order.

10.7 Storage

n

Important!

Pull out the mains plug and ventilate the equipment

and all connected pneumatic tools. Switch off the

compressor and make sure that it is secured in

such a way that it cannot be started up again by any

unauthorized person.

n

Important!

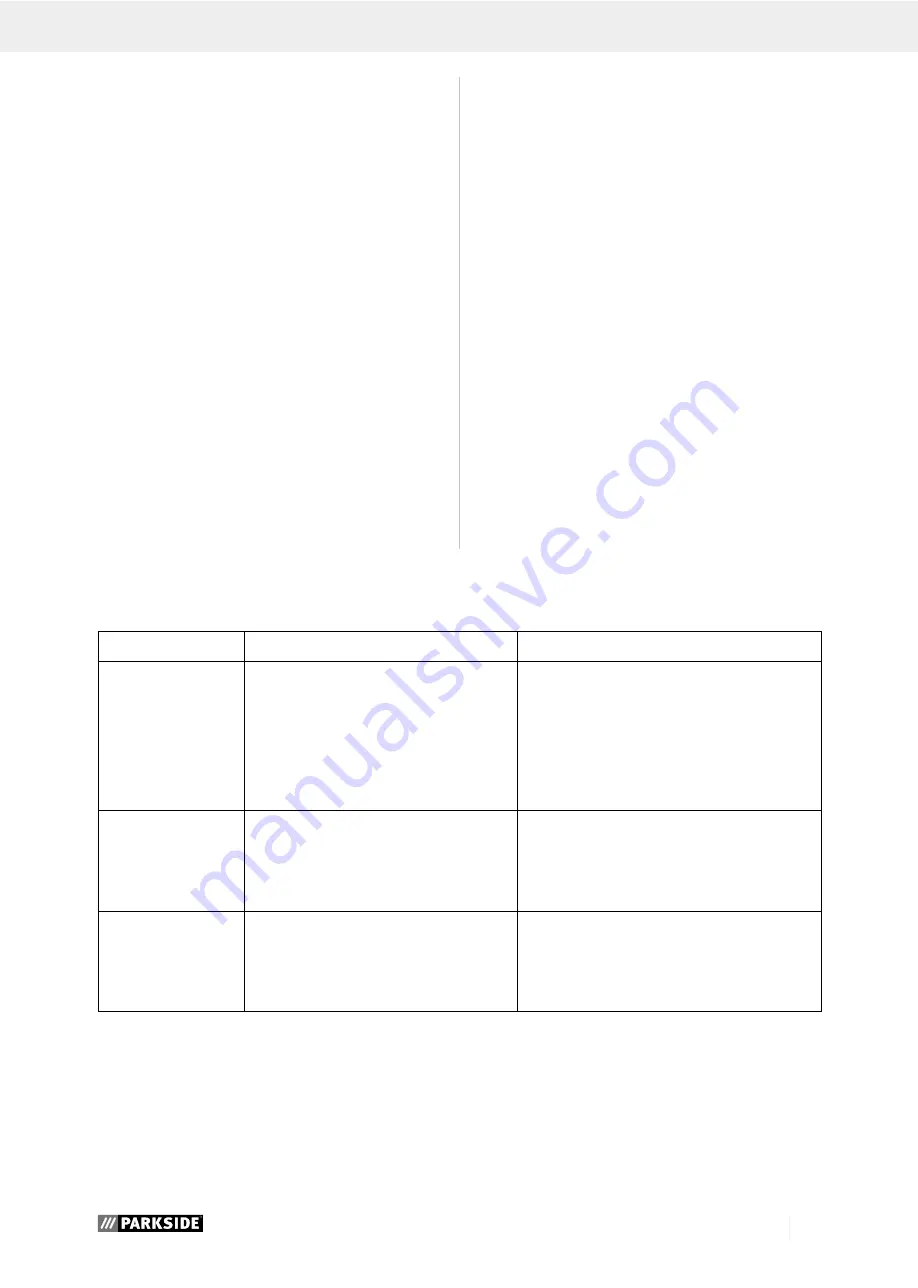

12. Troubleshooting

Fault

Possible cause

Remedy

The compressor does

not start.

• No supply voltage.

•

Insuffi cient supply voltage.

• Outside temperature is too low.

• Motor is overheated.

• Check the supply voltage, the power plug and the

socket-outlet.

• Make sure that the extension cable is not too

long. Use an extension cable with large enough

wires.

• Never operate with an outside temperature of

below +5° C.

• Allow the motor to cool down. If necessary,

remedy the cause of the overheating.

The compressor starts

but there is no pressure.

• The non-return valve leaks.

• The seals are damaged.

• The drain plug for condensation water (9)

leaks.

• Have a service center replace the non-return

valve.

• Check the seals and have any damaged seals

replaced by a service center.

• Tighten the screw by hand. Check the seal on the

screw and replace if necessary.

The compressor starts,

pressure is shown on

the pressure gauge, but

the tools do not start.

• The hose connections have a leak.

• A quick-lock coupling has a leak.

•

Insuffi cient pressure set on the pressure

regulator (3).

• Check the compressed air hose and tools and

replace if necessary.

• Check the quick-lock coupling and replace if

necessary.

• Increase the set pressure with the pressure

regulator.

Store the compressor only in a dry location which

is not accessible to unauthorized persons. Always

store upright, never tilted! Oil may leak out!

10.7.1 Releasing excess pressure

Release the excess pressure by switching off the com-

pressor and using the compressed air which is still left

in the pressure vessel, e.g. with a compressed air tool

running in idle mode or with a blow-out pistol.

11. Disposal and recycling

The equipment is supplied in packaging to prevent it

from being damaged in transit. The raw materials in

this packaging can be reused or recycled. The equip-

ment and its accessories are made of various types of

material, such as metal and plastic. Defective compo-

nents must be disposed of as special waste. Ask your

dealer or your local council.

Summary of Contents for 109808

Page 4: ...10 11 6 7 12 13 8 9 24 23 26 8 25 26 B A 16 21 18 max min 16 D E C C D F 15 G...

Page 30: ...25 BG 1 26 2 26 3 26 4 27 5 27 29 6 29 7 29 8 29 30 9 30 10 30 31 11 31 12 32 13 33 14 52...

Page 32: ...27 BG 4 270 5 n n 1 2 3 4 5 6 7 8 9 10 11 12 13 14...

Page 33: ...28 BG 15 16 17 18 19 20 21 55 C 30 m3 PVC...

Page 37: ...32 BG 12 1 2 3 4 1 2 3 5 C 4 1 2 3 9 1 2 3 1 2 3 3 1 2 3...

Page 41: ...36 GR CY min 5 n n 1 2 3 4 N 5 N 6 7 8 9 10 11 12 13 14...

Page 42: ...37 GR CY 15 16 17 18 19 20 21 55 C 30 PVC N O...

Page 46: ...41 GR CY 12 1 2 3 4 1 2 3 5 C 4 1 2 3 9 1 2 3 1 2 3 3 1 2 3...