7

GB/IE

Introduction

Introduction / Safety notices

the work location. Noise development at the work

location depends e.g. on the work environment, the

work piece, the work piece support and the number

of fastener driving processes.

In accordance with conditions at the work location,

individual noise reduction measures may need to

be carried out, such as placing the work piece on

a noise-suppressing surface, clamping or covering

to prevent work piece vibration and adjusting to the

minimum pressure required by the work process. In

certain cases, wearing personal hearing protection

is require.

Wear hearing protection!

Total vibration values in accordance with

ISO 28927-10, EN 12096:

Vibration emission value a

h

= 69.83 m / s

2

Uncertainty K = 1.5 m / s

2

Scope of delivery

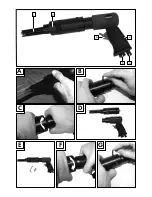

1 Needle scaler (head preinstalled)

1 Threaded plug nipple

1 Allen key

1 Instructions for use

Safety notices

General safety rules

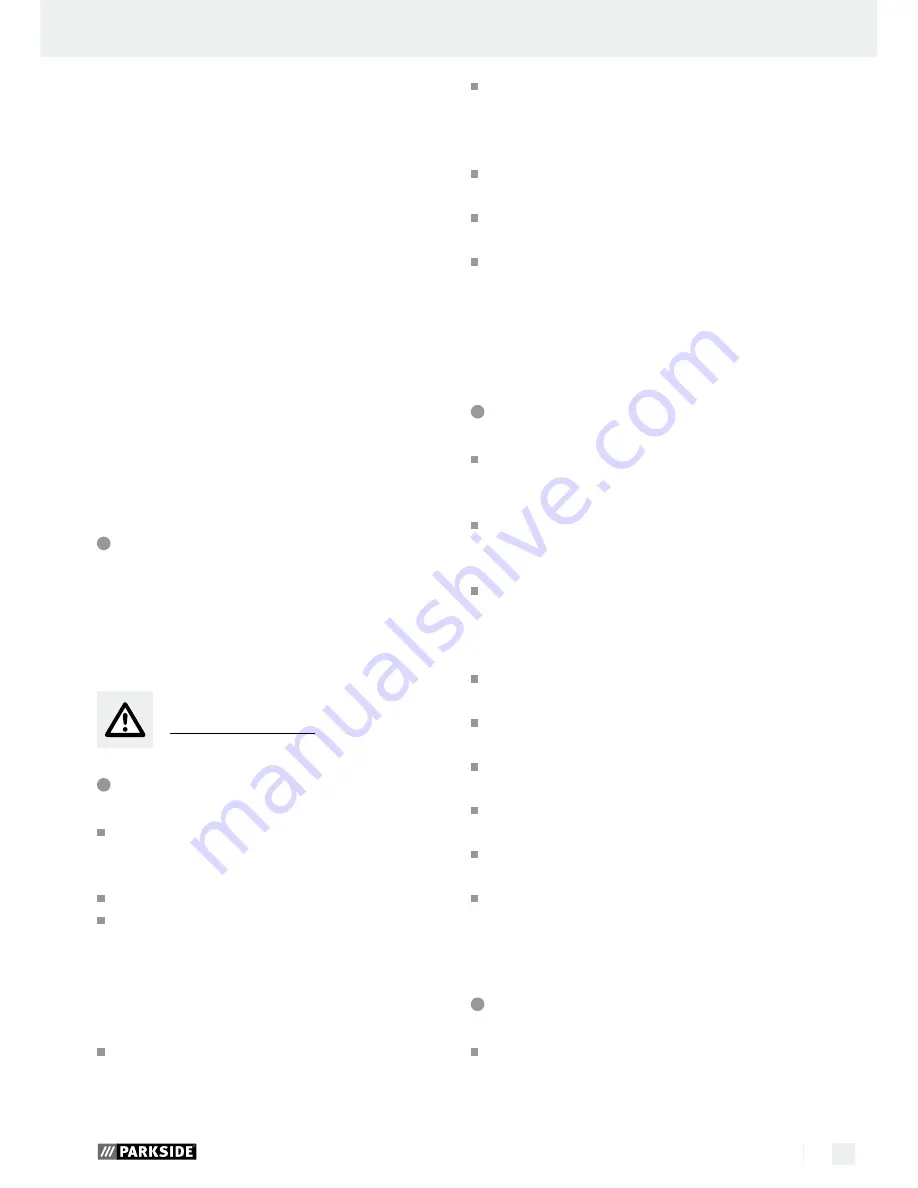

To connect the device to the air hose, never

point the front end (needle head) of the tool at

yourself or others.

Never point the tool at yourself or others.

In the cases of multiple hazards the safety in-

structions must be read and understood before

attaching, operating, repairing and exchanging

accessories and before working near the

non-rotating, percussive machine. Otherwise

severe bodily injuries may result.

The non-rotating, percussive machine should

only be set up, adjusted and used by qualified

and trained users.

Never modify the non-rotating, percussive

machine. Modifications may reduce the effec-

tiveness of safety measures and increase oper-

ator risks.

Do not lose the safety instructions – hand them

to the operator.

Never use a damaged non-rotating, percussive

machine.

Regularly maintain machines to verify all re-

quired rated values and markings required by

ISO 11148 are legible on the machine. If nec-

essary, the employee/user must contact the man-

ufacturer for replacement labels for markings.

Risks due to projected parts

Disconnect the non-rotating, percussive ma-

chine from the power supply before replacing

the inserted tool or accessories.

If the work piece, one of the accessories, or the

tool itself breaks, parts may be projected at a

great speed.

Always wear eye protection when operating

the non-rotating, percussive machine. The level

of required protection required should be as-

sessed individually for each application.

When working overhead, a safety helmet must

be worn.

In this case, the risk to other people must also

be assessed.

It must be ensured that the work-piece is prop-

erly secured.

Only operate the machine with the machine tool

secured in the machine with a suitable retainer.

To prevent injuries, any worn, broken or bent

parts of the retainer must be replaced.

Before switching on the machine, the machine

tool must be firmly applied to the surface you

will be working on.

Operating hazards

During uses, the operator‘s hands may be ex-

posed to hazards such as impact, cuts, abrasion

and heat. Wear suitable gloves to protect hands.