37

GB/MT

18

Replacing the power cable

–

To prevent hazards, leave the replacement of dam-

aged power cables strictly to the manufacturer or a

qualified electrician. There is a risk of electric shock!

19

Inflating tires

–

Directly after inflating tires, check the pressure with

a suitable pressure gauge, for example at your fill-

ing station.

20

Roadworthy compressors for building site operations

–

Make sure that all lines and fittings are suitable for

the maximum permissible operating pressure of the

compressor.

21

Place of installation

–

Set up the compressor on an even surface.

22

Supply hoses at pressures above 7 bar should be

equipped with a safety cable (e.g. a wire rope).

ADDITIONAL SAFETY INSTRUCTIONS

Safety instructions for working with compressed air

and blasting guns

•

The compressor pump and lines can become very hot dur-

ing operation. Touching these parts will burn you.

•

The air which is sucked in by the compressor must be kept

free of impurities that could cause fires or explosions in

the compressor pump.

•

When releasing the hose coupling, hold the hose cou-

pling piece with your hand. This way, you can protect

yourself against injury from the rebounding hose.

•

Wear safety goggles when working with the blow-out

pistol. Foreign bodies or blown off parts can easily cause

injuries.

•

Do not blow at people with the blow-out pistol and do not

clean clothes while being worn. Risk of injury!

Safety information for paint spraying

•

Do not process any paints or solvents with a flash point

below 55° C. There is a risk of explosion!

•

Do not heat up paints or solvents. There is a risk of ex-

plosion!

•

If hazardous liquids are processed, wear protective filter

units (face guards). Also, adhere to the safety information

provided by the manufacturers of such liquids.

•

The details and designations of the Ordinance on Haz-

ardous Substances, which are displayed on the outer

packaging of the processed material, must be observed.

•

Additional protective measures are to be undertaken if

necessary, particularly the wearing of suitable clothing

and masks.

•

Do not smoke during the spraying process and/or in the

work area. There is a risk of explosion! Paint vapors are

easily combustible.

•

Never set up or operate the equipment in the vicinity of a

fire place, open lights or sparking machines.

•

Do not store or eat food and drink in the work area. Paint

vapors are harmful to your health.

•

The work area must exceed 30 m

3

and sufficient ventila-

tion must be ensured during spraying and drying. Do not

spray against the wind. Always adhere to the regulations

of the local police authority when spraying combustible

or hazardous materials.

•

Do not process media such as white spirit, butyl alcohol

and methylene chloride with the PVC pressure hose. These

media will destroy the pressure hose.

Operating pressure vessels

•

You must keep your pressure vessel in good working or-

der, operate the vessel correctly, monitor the vessel, carry

out necessary maintenance and repair work immediately

and meet the relevant safety precautions.

•

The supervisory authority may enforce essential control

measures in individual cases.

•

A pressure vessel is not allowed to be used if it has faults

or deficiencies that can endanger workers or third parties.

•

Check the pressure vessel for signs of rust and damage

each time before using. Do not use the compressor with

a damaged or rusty pressure vessel. If you discover any

damage, then please contact the customer service work-

shop.

Do not lose these safety instructions

Residual risk

Observe the specified maintenance and safety instructions

in the instruction manual.

Always be attentive at work and keep third persons at a safe

distance from your workplace.

Even with proper use of the device, a certain residual risk

remains, which can not be excluded. The following poten-

tial hazards can be derived from the type and design of

the device:

•

unintentional commissioning of the product.

•

Hearing loss if no suitable hearing protection is worn.

•

Wear safety glasses to prevent your eyes and face from

dust and dirt particles.

•

Inhalation of whirled-up dust and dirt particles.

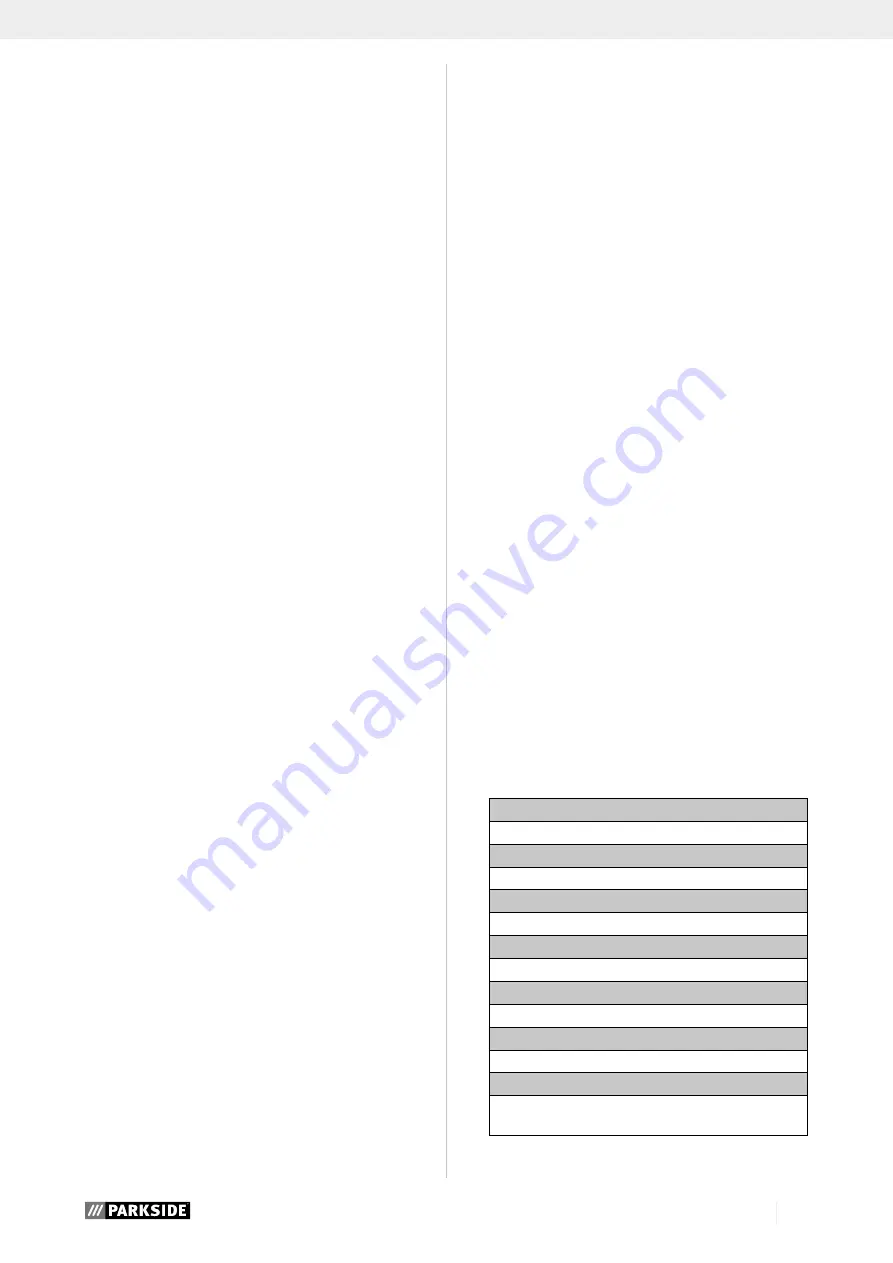

6. Technical data

Mains connection

230 V ~ 50Hz

Motor rating W

1800

Operating mode

S1

Compressor speed

2850 min

-1

Pressure vessel capacity (in liters)

approx. 24

Operating pressure

approx. 10 bar

Theoretical intake capacity (l/min)

approx. 260

sound power level L

PA

74.9 dB(A)

sound power level L

WA

94.9 dB(A)

uncertainty K

PA/WA

2.42 dB

Protection type

IP20

Weight of the unit in kg

approx. 27

Oil (15W 40) l

approx. 0,6

Max. altitude

(above mean sea level)

1000 m

Summary of Contents for 298828

Page 4: ...10 11 6 7 12 13 8 9 9 B A D E C C D F 15 max min 18 16 20 24 22 25 22 14 26 G ...

Page 51: ...52 ...

Page 53: ...54 ...

Page 55: ......