10

GB

9.8 Mitre cut 0°- 45° and turntable 0°- 45°

(fig. 1/8/10)

The multifunction sliding cross cut mitre saw can be used to

make mitre cuts to the left of 0°- 45° in relation to the work

face and, at the same time, 0° - 45° to the left or 0° - 45° to

the right in relation to the stop rail (double mitre cut).

Attention!

For 0°- 45° mitre cuts, the clamping device (7)

must only be mounted on the right side (see fig. 12-13).

Attention!

For mitre cuts (inclined saw head), the moveable

stop rail (16a) must be fixed in the outer position (

left side

).

• Open the set screw (16b) for the moveable stop rail (16a)

and push the moveable stop rail (16a) outwards.

• The moveable stop rail (16a) must be locked so that the dis-

tance between the stop rail (16a) and the saw blade (6) is

at least 8 mm.

• Before making a cut, check that the stop rail (16a) and the

saw blade (6) cannot collide.

• Re-tighten the set screw (16b).

• Move the machine head (4) to its upper position.

• Fold the locking handle (11) upwards to loosen the rotary

table (14) (fig. 3+4).

• Set the rotary table (14) to the desired angle (refer also to

point 9.5 in this regard).

• Fold the locking handle (11) downwards to secure the rotary

table (14) (fig. 3+4).

• Undo the set screw (22).

• Use the handle (1) to tilt the machine head (4) to the left until

it coincides with the required angle value (in this connection

see also section 9.7).

• Re-tighten the set screw (22).

• Cut as described under section 9.4.

9.9 Limiting the cutting depth (fig. 14)

• The cutting depth can be infinitely adjusted using the screw

(24). To do this loosen the knurled nut (24a) on the screw

(24). Turn the screw (24) in or out to set the required cutting

depth. Then re-tighten the knurled nut (24a) on the screw

(24).

• Check the setting by completing a test cut.

9.10 Changing the saw blade (fig. 2, 15-17)

Remove the power plug!

Attention!

Wear safety gloves when changing the saw blade.

Risk of injury!

• Swing the machine head (4) upwards and lock with the lock-

ing bolt (23).

• Use one hand to insert the Allen key (C) in the flange screw

(28).

• Firmly press the saw shaft lock (30) and slowly rotate the

flange screw (28) in clockwise direction. The saw shaft lock

(30) engages after no more than one rotation.

• Now, using a little more force, slacken the flange screw (29)

in the clockwise direction.

• Turn the flange screw (28) right out and remove the outer

flange (29).

• Fold the saw blade guard (5) upwards.

• Take the blade (6) off the inner flange (31) and pull out

downwards.

• Carefully clean the flange screw (28), outer flange (29) and

inner flange (31).

• Fit and fasten the new saw blade (6) in reverse order.

• Attention!

The cutting angle of the teeth, in other words

the direction of rotation of the saw blade (6) must coincide

with the direction of the arrow on the housing.

• Before continuing your work make sure that all safety de-

vices are in good working condition.

• Attention!

Every time that you change the saw blade (6),

check to see that it spins freely in the table insert (10, fig. 1)

in both perpendicular and 45° angle settings.

• Attention!

The work to change and align the saw blade

(6) must be carried out correctly.

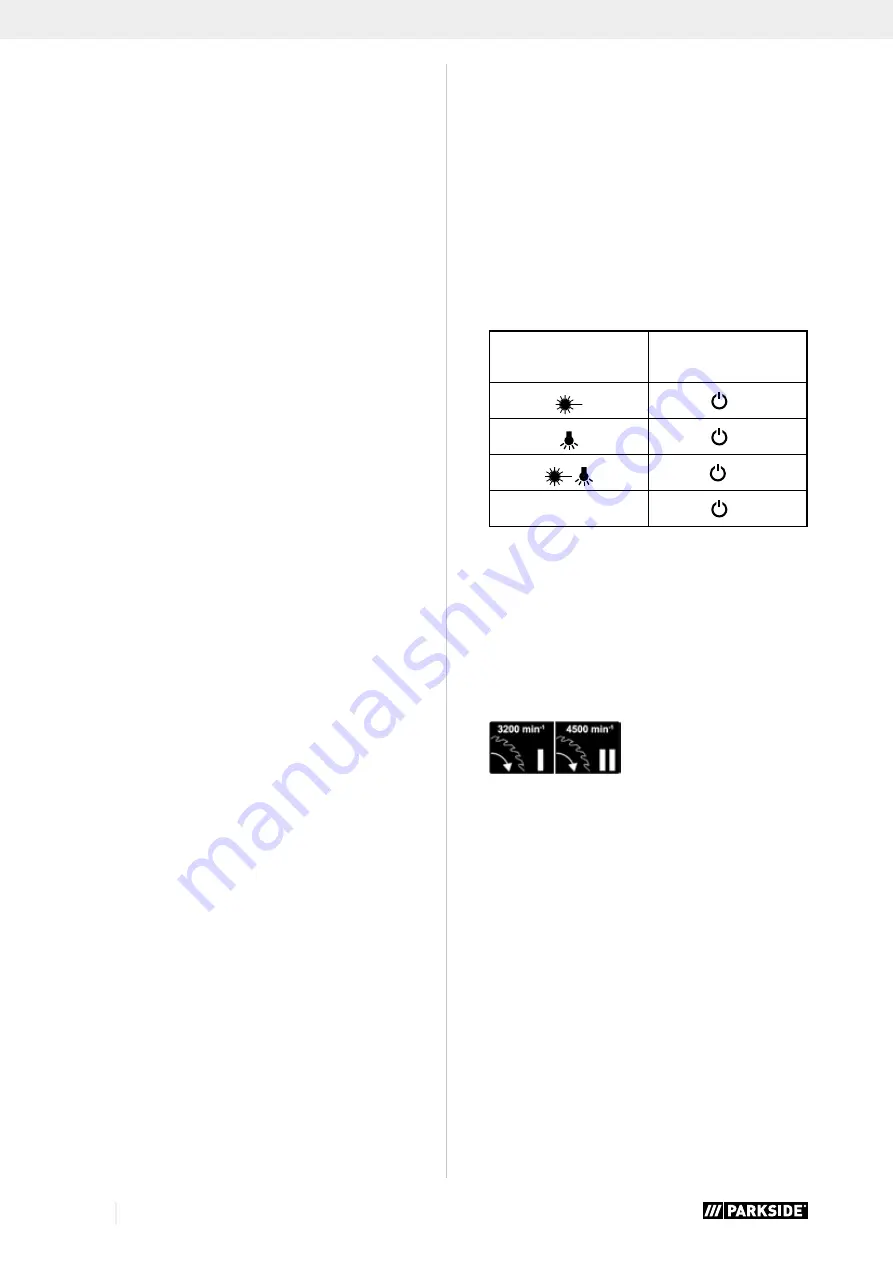

9.11 Using the laser / LED (fig. 18)

Function

Press the ON/OFF switch

laser/LED (33)

1x

1x

1x

.

OFF

1x

9.12 Adjusting the laser (fig. 19)

If the laser (32) ceases to indicate the correct cutting line, you

can readjust the laser. Loosen the Philips head screws (E) and

set the laser by moving sideways until the laser beam strikes the

teeth of the saw blade (6).

Firmly secure both screws (E).

9.13 Changing the speed (fig. 18)

The mitre saw has 2 speed ranges:

• To operate the mitre saw at a speed of 3200 rpm (metal), set

the speed regulation switch (34) to position I.

• To operate the saw at a speed of 5000 rpm (wood), set the

speed regulation switch (34) to position II.

10. Transport (fig. 2/3)

• Tighten the locking handle (11) to lock the rotary table.

• Press the machine head (4) downwards and secure with the

locking bolt (23).

• Fix the saw’s drag function with the locking screw for drag

guide (20) in rear position.

• Carry the equipment by the fixed saw table (15).

• When reassembling the equipment proceed as described

under section 8.

Summary of Contents for 339390 1910

Page 5: ...16 30 15 29 28 C 18 33 34 17 31 5 6 20 E 19 32 38 E E ...

Page 88: ...83 ...

Page 90: ......

Page 91: ......