PWSA 20-Li C3

GB

│

CY

│

13

■

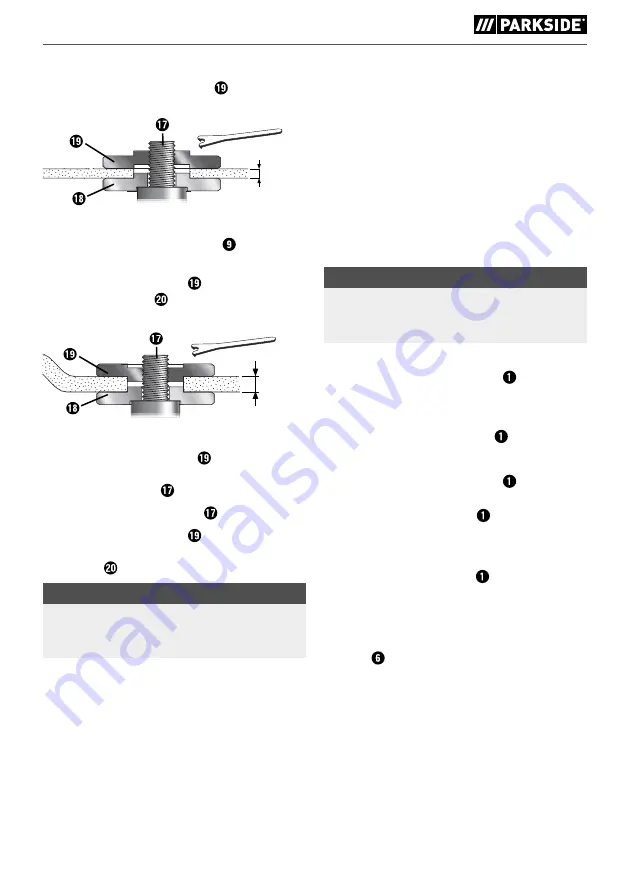

With thin grinding discs (see fig. 1)

♦

The collar of the clamping nut faces upwards

so that a thin grinding disc can be fitted safely.

12

≤ 3,2 mm

Fig. 1

♦

Press the spindle locking button to lock the

motor.

♦

Tighten the clamping nut using the two-hole

mounting spanner .

With thick grinding discs (see fig. 2)

> 3,2 mm

Fig. 2

The collar of the clamping nut faces downwards

so that the grinding disk can be fitted securely onto

the attachment spindle .

♦

Lock the attachment spindle .

♦

Tighten the clamping nut in a clockwise

direction using the two-hole mounting

spanner .

NOTE

►

If the disc does not turn smoothly or vibrates

after the change, the disc must be replaced

immediately.

♦

For safety's sake, run the appliance at maximum

speed for 60 seconds after every disc change.

Be aware of unusual noises and sparks.

♦

Check whether all the fastening elements are

correctly fitted.

♦

Make sure that the arrow showing the direction

of rotation (if any) on the cutting or rough

grinding discs (including diamond cutting discs)

and the direction of rotation of the appliance

(arrow showing the direction of rotation on the

head) match.

Operation

Switching on and off

Check the attached tool before use to ensure that

all fastening elements are correctly fitted.

NOTE

►

Always switch on the angle grinder before

making contact with the material, then apply

it to the workpiece.

Switching on:

♦

First, press the

ON/OFF switch to the right

so that you can then press it forwards.

Switching off:

♦

Let go of the ON/OFF switch .

Switching to continuous operation:

♦

First, press the

ON/OFF switch to the right

so that you can then press it forwards. Then

press the

ON/OFF switch forwards and

down until it engages.

Switching off continuous operation

♦

Press the

ON/OFF switch to the rear and

downwards and release it.

Adjusting the rotational speed

You can use the adjusting wheel for speed pre-

selection to preselect the rotational speed:

(1 = slower speed, 6 = faster speed).

We recommend you carry out practice tests to

determine the correct speed.

The speed can also be changed during operation.

Summary of Contents for 360196 2007

Page 3: ...B A ...

Page 4: ...D C E E 8a X ...

Page 41: ...PWSA 20 Li C3 36 HR ...

Page 99: ...PWSA 20 Li C3 94 BG ...

Page 119: ...PWSA 20 Li C3 114 GR CY ...

Page 139: ...PWSA 20 Li C3 134 DE AT CH ...