9

GB/CY

Preparing the product for use / Operation

Connect the device to a suitable compressed

air source.

1. To do so, press the compressed air hose quick-

release coupling (not included in the scope of

delivery) on the ¼" threaded nipple

4

of the

compressed air tacker.

Locking is automatic.

2. Connect the other end of the compressed air

hose to the (filter) pressure reducer on the com-

pressor.

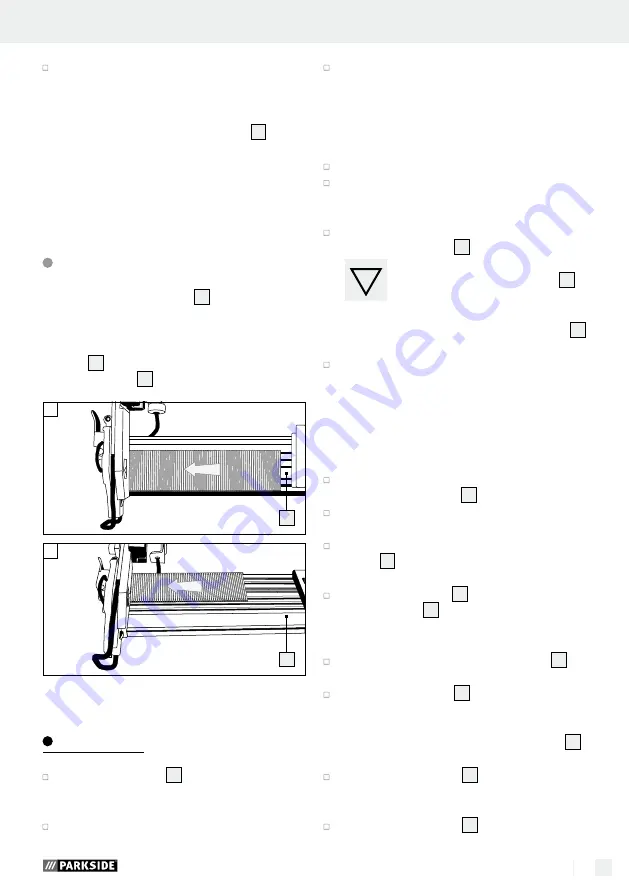

Loading the magazine

1. Press the magazine lever

5

and pull the mag-

azine cover back to its stop position.

2. Insert the corresponding fastener (nails, see

Fig. 01 or staples, see Fig. 02) into the maga-

zine

6

. The tacks must be put on the rail of

the magazine

6

.

02

6

01

6

3. Slide the magazine cover forwards until it locks.

Operation

Load the magazine

6

of the compressed air

tacker as described in the chapter “Loading the

magazine“.

Use the pressure reducer to set the correct

operating pressure.

Ensure that the permissible operating pressure

of 8 bar at the device is never exceeded.

Operating pressure that is too high does not

provide any performance increase, but only in-

creases compressed air consumption and ac-

celerates wear on the device.

Switch on the compressor.

Allow the compressor to run once long enough

until maximum tank pressure is reached and the

device is switched off.

Place the compressed air tacker on the workpiece

and press the trigger

2

.

NOTE:

The compressed air tacker

is equipped with a trigger lock

9

.

The fastener will only leave the device

when the mouth of the compressed air tacker is

pressed against the workpiece and the trigger

2

is actuated.

Check that the fastener has been driven in cor-

responding to the work requirements.

– If the fastener is protruding, increase the air

pressure in 0.5 bar increments.

– If the fastener is too deep, decrease the air

pressure in 0.5 bar increments.

As an alternative, you can accelerate the work

by keeping the trigger

2

depressed.

Set the compressed air tacker against the work-

piece.

Press the device against the workpiece until the

mouth

10

touches it. The fastener will leave the

device.

As long as the trigger

2

is kept depressed, each

time the mouth

10

touches the workpiece one

fastener will leave the device.

Another alternative is to keep the mouth

10

pressed against the workpiece.

Each time the trigger

2

is actuated, a fastener

will leave the device.

NOTE:

Fine adjustment with the knurled screw

8

is possible.

Turn the knurled screw

8

downwards in order

to drive the fastener more deeply into the work-

piece.

Turn the knurled screw

8

upwards in order to

drive the fastener less deeply into the workpiece.

Safety of the fastener driving tool / Preparing the product for use

Summary of Contents for 96899

Page 3: ...A 3 4 1 2 6 7 8 9 12 11 10 5...

Page 4: ...B C D...

Page 12: ...12...

Page 20: ...20...

Page 32: ...32 BG 8bar e 9...

Page 33: ...33 BG 8 bar 1 4 2 1 5 2 01 02 6 6 02 6 01 6 3 6...

Page 34: ...34 BG 8bar 2 9 2 0 5bar 0 5bar 2 10 2 10 10 2 8 8 8 1 6 11 12 9 11 12 1 6...

Page 35: ...35 BG 5000 1 2 4 2 3...

Page 37: ...37 GR CY 38 38 38 38 39 40 41 41 41 41 42 42 43 43 43 44 44...

Page 39: ...39 GR CY ISO 8662 11 1999 ah W 15 0m s2 0 29m s2 ISO 8662 11 1999...

Page 40: ...40 GR CY 8bar 9...

Page 41: ...41 GR CY 8 bar 1 4 2 1 5 2 01 02 6 6 02 6 01 6 3 6 8bar...

Page 42: ...42 GR CY 2 9 2 0 5bar 0 5bar 2 10 2 10 10 2 8 8 8 1 6 11 12 9 11 12 1 6...

Page 43: ...43 GR CY 5000 1 2 4 2 3...