26

GB

Noise can have serious effects on your health. If the device

noise exceeds 85 dB (A), please wear suitable hearing pro-

tection.

Noise

Sound pressure level L

pA

.................................................... 87 dB

Uncertainty K

pA

.................................................................... 3 dB

Sound power level L

WA

....................................................107 dB

Uncertainty K

WA

..............................................................1.87 dB

Guaranteed Sound power level L

WA

...............................109 dB

Wear hearing protection.

Excessive noise can result in a loss of hearing.

The specified device emissions values have been measured in

accordance with a standardised test procedure and can be

used for the comparison of one tool with another.

The specified noise emission values can also be used for an

initial estimation of the exposure.

Vibration

Top handle....................................................................5.28 m/s

2

Bottom handle ............................................................. 5.56 m/s

2

Uncertainty K .................................................................1.5 m/s

2

Keep the noise level and vibration to a minimum!

• Only use devices which are free of defects.

• Maintain and clean the device at regular intervals.

• Adapt your working methods to the device.

• Do not overload the device.

• Have the device checked if necessary.

• Switch the device off if it is not in use.

• Wear gloves.

WARNING

Avoid the risks associated with vibration, e.g. the risk of white

finger syndrome (circulatory disorders) by taking frequent

breaks from work where you rub your palms together, for ex-

ample.

• Always wear protective gloves and make sure your hands

are warm.

• Take regular breaks from work.

8. Unpacking

• Open the packaging and carefully remove the device.

• Remove the packaging material, as well as the packaging

and transport safety devices (if present).

• Check whether the scope of delivery is complete.

• Check the device and accessory parts for transport dam-

age.

• If possible, keep the packaging until the expiry of the war-

ranty period.

m

DANGER

The device and the packaging are not children‘s

toys! Do not let children play with plastic bags,

films or small parts! There is a danger of choking

or suffocating!

9. Assembly

The device can be used both as a petrol leaf blower and as a

petrol leaf vacuum. It is necessary to set up the device in ac-

cordance with the respective purpose.

Note

Always set up the device on a level and stable surface.

9.1

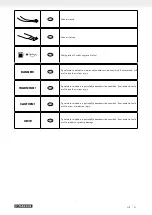

Leaf blower assembly (Fig. 2 + 3)

9.1.1 Fit the blast pipe (4) to the motor unit (10)

(Fig. 2):

1. Remove the locking screw (5) on the blast connection (6)

of the motor unit (10).

2. Align the attachment point (A) of the blast pipe (4) with

the projection (B) of the blowgun (6).

3. Slide the blast pipe (4) into the blasting connection (6).

4. Retighten the locking screw (5).

9.1.2 Fit the flat nozzle (1) / round nozzle (2) to

the blast pipe (4) (Fig. 3):

The petrol leaf blower can be operated with a flat nozzle (1)

or a round nozzle (2).

1. Align the flat nozzle (1) / round nozzle (2) with the pro-

jection (C) of the blast pipe (4).

2. Push the flat nozzle (1) / round nozzle (2) and the blast

pipe (4) together and turn them 90° clockwise.

3. Tighten the locking screw (3).

Note

The petrol leaf blower is correctly mounted when the flat noz-

zle (1) / round nozzle (2) points towards the ground.

Note

The petrol leaf blower cannot be started if the blast pipe (4)

is not fitted.

9.2

Leaf vacuum assembly (Fig. 4 - 9)

m

CAUTION:

Always make sure the device is fully assembled

before commissioning!

9.2.1 Fit the vacuum tube (14) to the motor unit

(10) (Fig. 4, 5):

1. Open the protective grille (11) by sliding the catch (D) to the

side. Use a suitable tool for this (e.g. a slotted screwdriver).

2. Fold open the protective grille (11).

3. Fit the vacuum tube (14) to the vacuum connection (29).

The grooves (E) in the vacuum tube (14) must match the

pins on the vacuum connection (29).

4. Turn the vacuum tube (14) clockwise as far as it will go to

secure the vacuum tube (14).

9.2.2 Fit the suction nozzle (12) to the vacuum

tube (14) (Fig. 6):

1. Align the suction nozzle (12) with the pin (F) of the vac-

uum tube (14).

2. Push the suction nozzle (12) and the vacuum tube (14)

together and turn them 90° clockwise.

3. Tighten the locking screw (13).

Summary of Contents for PBLS 26 A1

Page 4: ...10 16 13 6 14 F 12 13 7 G 6 18 5 8 18 24 9 18 24 10 14 12 11 15 12 19 20 15 B 10...

Page 5: ...16 14 26 25 17 H 17 33 32 31 25 26 15 30 17 H...

Page 41: ...36...

Page 42: ......

Page 43: ......