30

GB

Note

Never immerse the device in water or other liquids for cleaning.

• Keep protective devices, air vents and the engine housing

as free of dust and dirt as possible. Blow it out with low-

pressure compressed air.

• To reduce the risk of fire, regularly clean the cooling fins of

the engine with compressed air. Clear the silencer area of

dust, leaves or other foreign objects.

• Clean the device at regular intervals using a damp cloth

and a little detergent. Make sure that no water can pen-

etrate the device interior.

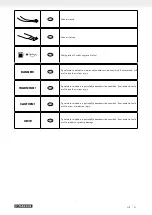

When used as a leaf blower:

• Clean the blast pipe (4) and flat nozzle (1) / round nozzle

(2) with a brush when dirty.

When used as a leaf vacuum:

• After finishing work, remove the collection bag (24), turn

it inside out and clean it thoroughly and dry it if necessary

to prevent mould and unpleasant odours from developing.

• A heavily soiled collection bag (24) can be washed with

soap and water and then dried.

• If the zip is difficult to operate, rub the zip teeth with a dry

soap bar.

• Clean the vacuum tube (14), suction nozzle (12) and outlet

tube (18) with a brush if they are dirty.

13.2 Maintenance

CAUTION

Always switch off the device and disconnect the spark plug

connector before maintenance work (see chapter 13.2.2

Spark plug maintenance).

All protective and safety equipment must be reassembled im-

mediately after repair, maintenance is completed.

13.2.1 Carburettor setting maintenance

If the engine stops by itself when the throttle is released, a

carburettor adjustment must be made.

Have carburettor adjustments (e.g. idle speed adjustment) car-

ried out only by qualified specialists to avoid engine damage.

13.2.2 Spark plug maintenance (Fig. 14, 15, 16)

1. Remove the spark plug connector cover (17). To do this,

loosen the screw (H). (Fig. 14, 15)

2. Pull off the spark plug connector (30).

3. Loosen the spark plug with the enclosed spark plug

wrench (28).

Electrode gap = 0.6 - 0.7 mm (distance between the elec-

trodes, between which the ignition spark is generated).

Check the spark plug for dirt and grime after 10 operating

hours and if necessary, clean it with a copper wire brush. Then

service the spark plug every 50 operating hours.

4. The re-assembly takes place in reverse order.

13.2.3 Fuel filter maintenance

Inside the fuel tank (22) there is a filter that prevents impurities

from entering the engine. The filter should be replaced once a

year by your dealer.

13.2.4 Air filter maintenance (fig. 14, 17)

Fouled air filters diminish the engine output due to reduced air

supply to the carburettor.

Regular inspection is therefore essential. The foam insert (31),

non-woven insert (32) and the metal insert (33) should be

checked regularly and cleaned if necessary.

If the air is very dusty, check the foam insert (31), non-woven

insert (32) and the metal insert (33) more frequently.

1. Loosen the air filter screw (26) by turning anti-clockwise.

2. Remove the cover (25).

3. Remove the foam insert (31), non-woven insert (32) and

the metal insert (33).

4. Clean the foam insert (31), non-woven insert (32) and the

metal insert (33) by knocking or blowing them out (with

compressed air).

5. The re-assembly takes place in reverse order.

WARNING

Never clean the air filter foam insert (31), air filter non-woven

insert (32) or the air filter metal insert (33) with petrol or flam-

mable solvents.

13.3 Important note in the case of repairs:

When returning the device for repair, for safety reasons, en-

sure that it is free of oil and fuel when it is sent to the service

centre.

13.3.1 Draining the fuel-oil mixture

In case of storage over a longer period of time, the petrol must

be drained.

Only empty the tank outdoors or in well-ventilated rooms.

Make sure that no fuel gets into the soil (environmental protec-

tion). Use a suitable collection container (not included in the

scope of delivery).

• Unscrew and remove the tank cover (23).

• Carefully pour the fuel-oil mixture from the tank into a suit-

able container.

• Drain the fuel-oil mixture completely.

• Screw the tank filler cap (23) back on by hand.

13.3.2 Ordering spare parts

Please provide the following information when ordering spare

parts;

• Device type

• Device article number

Service information

With this product, it is necessary to note that the following

parts are subject to natural or usage-related wear, or that the

following parts are required as consumables.

Wearing parts*: Spark plug, air filter, fuel filter, collection bag

* may not be included in the scope of supply!

Summary of Contents for PBLS 26 A1

Page 4: ...10 16 13 6 14 F 12 13 7 G 6 18 5 8 18 24 9 18 24 10 14 12 11 15 12 19 20 15 B 10...

Page 5: ...16 14 26 25 17 H 17 33 32 31 25 26 15 30 17 H...

Page 41: ...36...

Page 42: ......

Page 43: ......