9

GB/IE/CY

Initial use

dispersion and results in too rapid evaporation of

the liquid. The surfaces become rough and develop

poor adhesion properties. If the working pressure is

too low on the other hand, the paint material is not

sufficiently atomised. Undulating surfaces and the

formation of drops are the result.

Connect the compressed air hose with the

rapid-release coupling to the compressed air

connection

6

of the device. This automatically

locks into place.

Use the filter pressure reducer of the compressed

air source to set the working pressure to 3 bar.

Preparing the spraying surface

Mask off the surroundings of the spraying sur-

face thoroughly over a wide area. Otherwise

all non-covered areas or surfaces may become

soiled.

Make sure that the spraying surface is clean,

dry and free of grease.

Roughen smooth surfaces and then remove the

sanding dust.

Turning the device On / Off

Working Instructions:

-

When working with the device you should open

the vent

1

.

-

When diluting the material, make sure that the

spraying material and the dilution are suitable

for one another. If an incorrect dilution is used,

lumps may form and clog the gun as a result.

-

Screw the flow cup

3

clockwise firmly on to

the gun.

-

Fill the spraying material into the flow cup

3

and screw the lid

2

on tight.

-

Always hold the paint spray gun at the same

distance from the object. The ideal spraying

distance is approximately 15 cm.

-

Determine the appropriate settings in each

case by experimenting.

-

Do not turn the device on / off when it is over

the spraying surface, but start and end the

spraying process approximately 10 cm outside

of the spraying area.

Press the trigger

8

to start spraying and keep

it held down.

In order to stop spraying, release the trigger

8

again.

Adjusting the paint jet

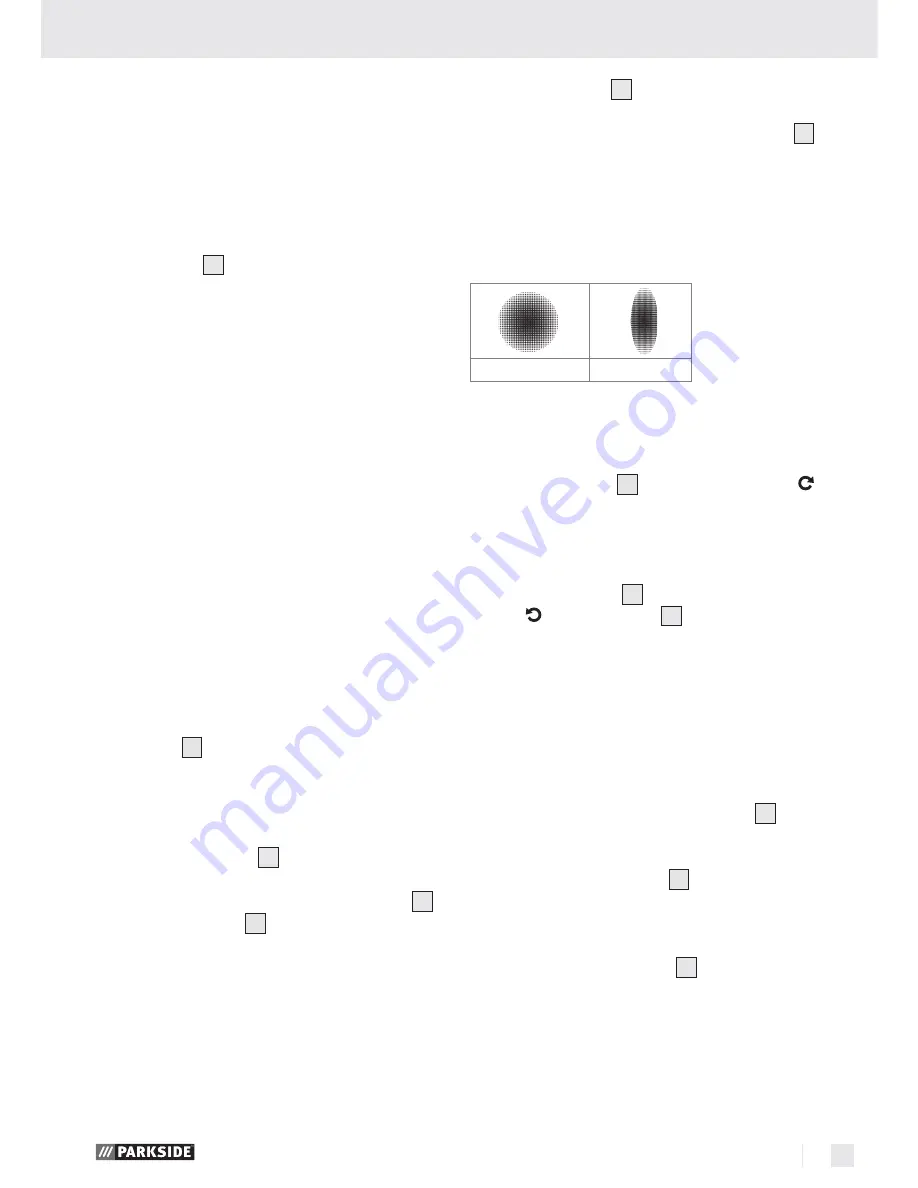

The device has the settings round and broad jet.

Round jet

Broad jet

Adjusting the round jet:

Use the round jet, for example, for small surfaces,

corners and edges.

Turn the regulator

5

in a clockwise direction .

Adjusting the broad jet:

Use the broad jet vertically and horizontally

over larger areas.

Turn the regulator

5

in an anticlockwise direc-

tion . The nozzle head

9

can be continuously

adjusted vertically and horizontally by turning

to the desired position.

Regulating the

quantity of paint

Note:

The front locking screw is used to limit the

adjustment range of the stroke stop screw

4

.

Increasing the quantity of paint:

Turn the stroke stop screw

4

in an anticlockwise

direction.

Reducing the quantity of paint:

Turn the stroke stop screw

4

in a clockwise

direction.

Regulating the quantity of air

Note:

It is advisable to start with the maximum

amount of air. In order to do this, open the air volume

Summary of Contents for PDFP 500 A1 - 3

Page 3: ...A B C D 5 2 3 4 6 7 8 9 1 11 13 12 13 10 11 13...

Page 11: ...12...

Page 19: ...20...

Page 20: ...21 GR CY E 22 22 22 23 23 24 24 HVLP 25 25 25 25 26 26 26 26 27 27 27 28...

Page 21: ...22 GR CY E PDFP 500 A1 E 1 2 3 4 5 6 7 8 9 10 11 12 13 1 PDFP 500 A1 1 1 1 1 1...

Page 23: ...24 GR CY 21 C...

Page 24: ...25 GR CY HVLP HVLP High Volume Low Pressure 3 bar 8bar 6 3 bar 1 3 3 2 15cm 10 cm...

Page 25: ...26 GR CY 8 8 5 5 9 4 4 4 7 7 7...