GB

│

IE

│

NI

│

7

■

PDFS 1300 A1

Further safety instructions for

abrasive cutting applications

Kickback and corresponding safety instruc-

tions

Kickback – causes and corresponding safety

instructions

▯

Kickback is a sudden reaction caused when a

rotating grinding disc catches or jams . Catching

or jamming causes the rotating accessory tool

to stop abruptly . If this happens, an uncontrolled

power tool turns rapidly against the direction

of rotation of the accessory tool caught in the

blockage .

▯

If, for example, a grinding disc catches or jams,

the edge of the grinding disc that is projecting

into the workpiece can get caught and break

off the grinding disc or cause a kickback . The

grinding disc can then fly in the direction of the

operator or away from him, depending on the

direction of rotation of the disc at the blockage .

This can also break grinding discs .

A kickback is caused by improper or incorrect use

of the power tool . This can be avoided by taking

proper precautions as described below .

a)

Hold the power tool firmly in both hands

and position your body and arms so they

can absorb the force of a kickback. Always

use the auxiliary handle, if available, so that

you have the maximum possible control over

the kickback force or reaction forces at full

speed.

By taking adequate precautions, the

operator can stay in control of the kickback and

reaction forces .

b)

Never hold your hand close to a rotating

accessory tool.

The accessory tool can jump

out of your hand if there is a kickback .

c)

Avoid the area in front of and behind the

rotating cutting disc.

The kickback will force

the electrical tool in the opposite direction to the

direction of rotation of the grinding disc at the

blockage .

d)

Take special care when working near corners,

sharp edges, etc. Avoid allowing the accessory

tool to bounce back from the workpiece or

jam.

The rotating accessory tool is more likely to

jam in corners or sharp edges or if it bounces .

This can cause a loss of control or kickback .

e)

Do not use chained or toothed cutting discs

or segmented diamond discs with slots more

than 10 mm wide

. Such accessories often

cause a kickback or loss of control over the

power tool .

f)

Avoid cutting disc jams or excessive contact

pressure. Do not make any excessively deep

cuts.

Overloading the cutting disc increases the

stress and likelihood of tilting or blocking and

thus the possibility of a kickback or a breakage

of the grinding tool .

g)

If the cutting disc jams or you stop working,

switch the tool off and hold it steady until the

disc has completely stopped turning. Never

attempt to pull a rotating cutting disc out of a

cut. This could lead to kickback.

Identify and

remove the cause of the jam .

h)

Do not switch the power tool back on as long

as it is in the workpiece. Allow the cutting disc

to reach its full speed before you carefully

continue the cut.

Otherwise, the disc may jam,

jump out of the workpiece or cause kickback .

i)

Support panels or large workpieces to re-

duce the risk of the cutting disc jamming and

causing a kickback.

Large workpieces can

bend under their own weight . The workpiece

must be supported on both sides, namely in the

vicinity of the cut and also at the edge .

Summary of Contents for PDFS 1300 A1

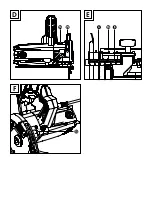

Page 3: ...A B C ...

Page 4: ...E D F ...