GB

│

IE

│

NI

│

9

■

PDFS 1300 A1

Assembly

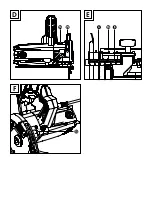

Fitting/changing the cutting disc

WARNING! RISK OF INJURY!

■

Switch the appliance off and remove the

power plug before starting any work on the

appliance .

NOTE

■

Only use diamond cutting discs with diame-

ters corresponding to the inscriptions on the

appliance .

♦

Set the cutting depth (using the locking screw

) to the minimum position .

♦

Actuate the spindle lock and turn the clamping

screw until the spindle lock clicks into

place . Loosen the clamping screw / washer

with the hex key . Now remove the clamping

screw / washer and the clamping flange

(see also fold-out page, fig . A) .

♦

Remove the cutting disc .

♦

Fitting a cutting disc is carried out in the

reverse order .

♦

Actuate the spindle lock and turn the clamping

screw until the spindle lock clicks into

place . Use the hex key to firmly tighten the

clamping screw .

WARNING!

►

The arrow on the cutting disc must match

the direction of rotation arrow (running direc-

tion, marked on the appliance) .

■

Make sure that the cutting disc is suitable for

the speed of the tool .

Fitting/setting the rip fence

♦

Undo the wing screw and insert the rip fence

into the rip fence slot .

♦

Set the desired cutting width using the scale on

the rip fence and the rip fence slot . The

rip fence slot serves as an orientation mark

(see also fold-out page, fig . E) .

♦

Retighten the wing screw .

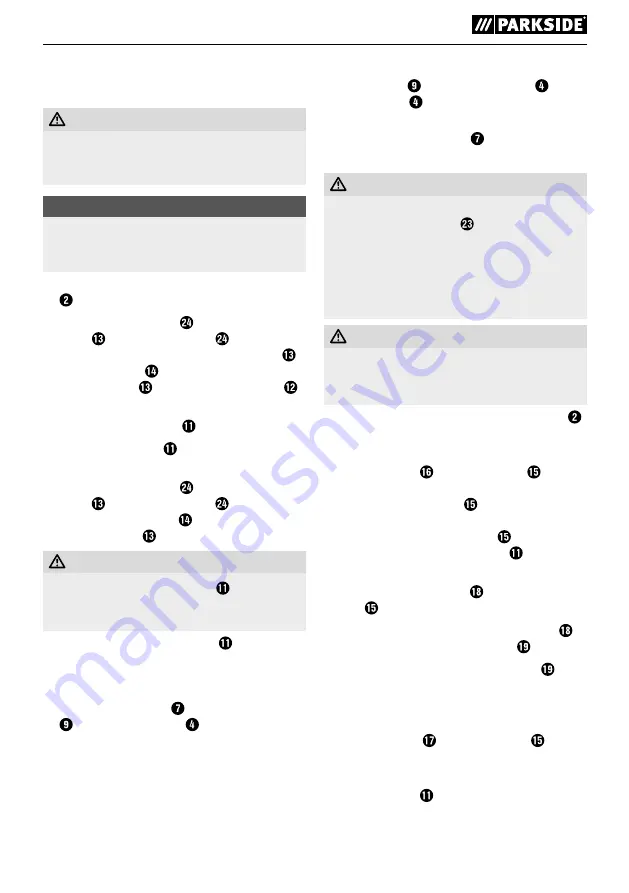

Fitting the water inlet hose

WARNING!

►

Check the correct function of the residual

current circuit breaker before each use!

►

Work with the appliance in a horizontal

position and not overhead to prevent water

from entering the machine .

►

Before each use, check the water supply

system for leaks .

CAUTION!

►

Do not connect the appliance to a water

supply system with more than 6 bar!

►

Only use water as coolant .

♦

Set the cutting depth (using the locking screw )

to the minimum position .

♦

Using a Phillips screwdriver and the accessory

screw supplied , fit the water inlet to the

housing (see also fold-out page, fig . B) . Please

note that the water inlet must be guided

around the cutting depth adjustment . The two

water outlets of the water inlet must be locat-

ed on the side of the cutting disc (see also

fold-out page, fig . F) .

♦

Push the water inlet hose into the water

inlet .

♦

Insert the other end of the water inlet hose

into the water connection adapter .

♦

Connect the water connection adapter to a

water hose with a suitable diameter of approx .

19 mm . Check for a tight fit by pulling on the

water hose .

♦

Open the valve on the water inlet .

♦

Carefully adjust the amount of water at the water

source so that there is always enough water on

the cutting disc and the cutting area .

♦

Disconnect the water supply after completion

of the work .

Summary of Contents for PDFS 1300 A1

Page 3: ...A B C ...

Page 4: ...E D F ...