■

10

│

GB

│

IE

│

NI

PDFS 1300 A1

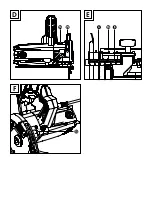

Installing the dust extraction system

On delivery, the connection point of the adapter

for dust extraction is closed off . To install the

dust extractor, proceed as follows:

♦

Remove the screws from the housing and

remove the protective cover .

♦

Using the screws provided, fasten the adapter

for dust extraction onto the dust outlet .

♦

Connect an approved dust and chip extraction

device .

Operation

WARNING!

►

Prevent dripping water from dripping along

the power cord into the power outlet or plug .

To do this, form a loop from the mains cable

underneath the mains socket . This prevents

any dripping water from getting into the

mains socket .

Residual current circuit breaker

WARNING!

►

Check the correct function of the residual

current circuit breaker before each use !

♦

Connect the residual current circuit breaker

to the power grid .

♦

Press the reset button until the indicator

is red .

♦

Press the Test button until the indicator is

black . This shows that the test was successful .

If the indicator continues to indicate red, the

residual current circuit breaker is defective

and must be repaired by qualified personnel!

WARNING!

►

Do not operate a appliance with faulty circuit

breakers!

♦

After a successful test, press the reset button

again to switch the appliance back on .

Switching on and off

WARNING!

►

To avoid the risk of electric shock, make sure

that no water gets into the appliance . Do not

touch the power plug with wet hands .

CAUTION!

►

Wait until the appliance has reached the

maximum speed and use a low feed rate to

achieve clean cuts .

Switching on:

♦

Press the ON/OFF switch .

Switching off:

♦

Release the ON/OFF switch .

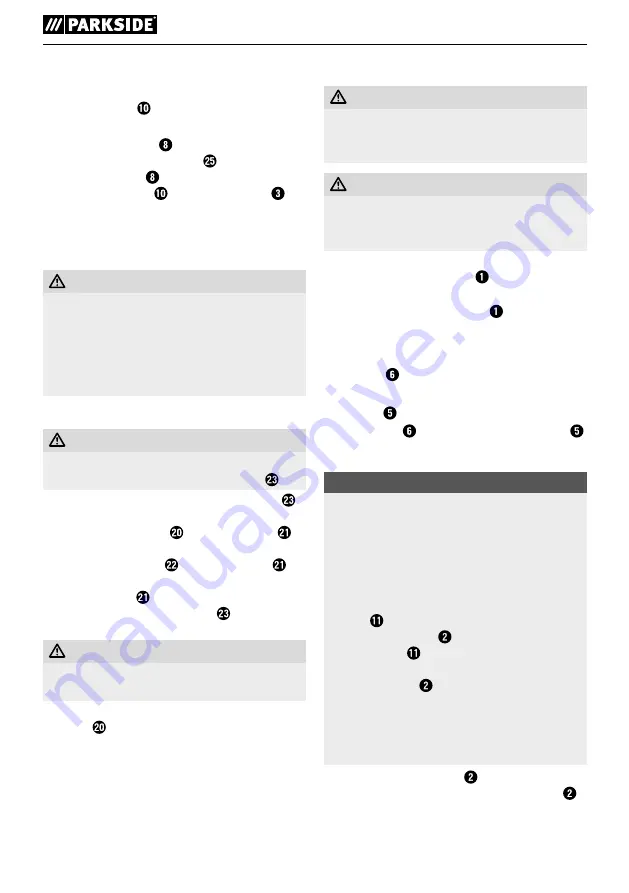

Setting the cutting angle

You can change the cutting angle using the cutting

angle scale .

■

Undo the wing screw of the cutting angle pre-

selector . Set the desired angle on the cutting

angle scale and retighten the wing screw .

Setting the cutting depth

NOTE

►

We recommend that the cutting depth should

be approx . 3 mm greater than the material

thickness . This ensures that you achieve a

clean cut .

►

To determine the correct setting, you can

place the machine on the edge of the

material to be machined so that the cutting

disc can swing freely downwards when

the locking screw is loosened . Once the

cutting disc protrudes approx . 3 mm

beyond the material thickness, tighten the

locking screw .

►

Use a similar procedure if you want to mill

a groove .

►

We recommend testing the setting on a sample

piece of material .

♦

Undo the locking screw . Set the desired

cutting depth and tighten the locking screw

again .

Summary of Contents for PDFS 1300 A1

Page 3: ...A B C ...

Page 4: ...E D F ...