19

GB

The electric arc is ignited in the weld

groove, guided to the continuation point,

melted properly and finally the weld

seam is continued.

CAUTION:

Please note that the torch

must always has to be placed on down

an insulated surface after welding.

Always switch off the welding device

after completing welding work and

during breaks and pull the plug from

the mains socket.

z

Create a weld seam

Forehand welding

Push the torch forwards.

Result: The penetration depth is lower,

broader weld width, flatter weld bead

(visible surface of the seam) and greater

fusion error tolerance.

Backhand welding

The torch is dragged from the weld seam.

Result: Greater penetration depth, narrower

weld width, higher weld bead and lower

fusion error tolerance.

Welded joints

There are two-basic types of joints in

welding: Butt welds and angle welding

(outer edge, inner edge and overlapping).

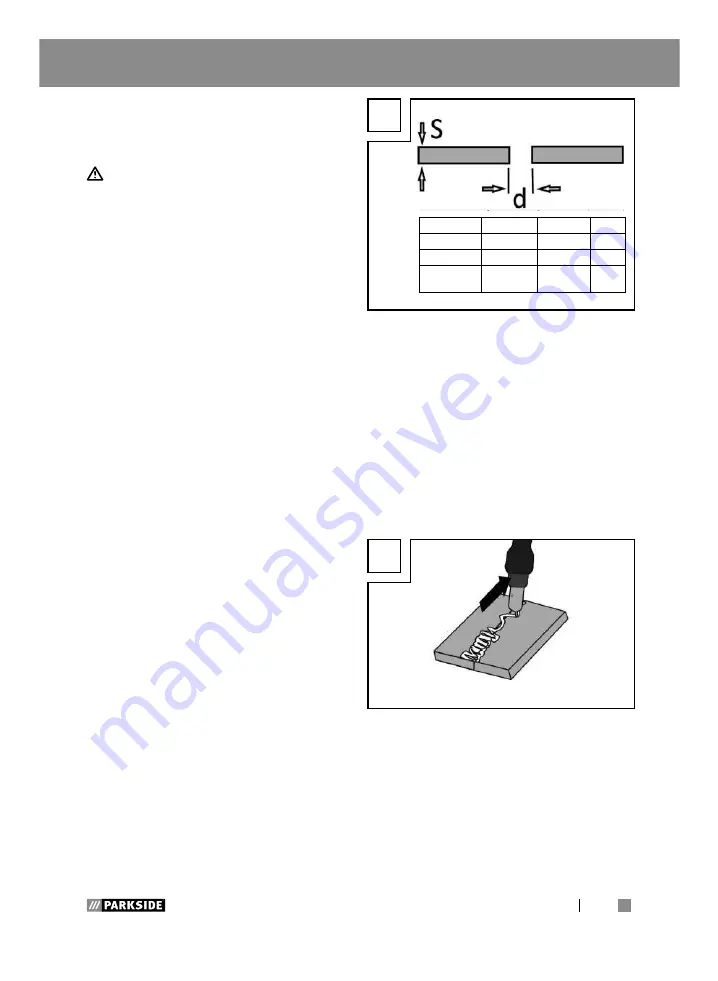

Butt welds

With butt welds of up to 2 mm, the weld

edges are completely brought together.

For greater thicknesses, please proceed

as per the following table:

S

S =

1-3 mm

3-4 mm

4-6 mm

d = surface

0.5-1.5- mm 1.5-2.5 mm 2-3 mm

d = vertical

1-1.5- mm

1.5-2.5 mm 2-3 mm

d = front

surface

1-2 mm

2-3 mm

3-4 mm

Flat butt welds

Welds should be made without interruption

and with a sufficient penetration depth.

Therefore, it is extremely important to be

well prepared. The factors that influence the

quality of the weld result are: the amperage,

the distance between weld edges, the

inclination of the torch and the correspond-

ing diameter of the welding wire.

The steeper you hold the torch against the

workpiece, the higher the penetration depth

and vice versa.

T

To forestall or reduce deformations that can

happen during the material hardening pro-

cess, it is good to fix the workpiece with a

device. Avoid stiffening the welded structure

to prevent cracks in the weld.

These problems can be avoided if there is a

possibility of turning the workpiece so that

the weld can be carried out in two passes

running in opposite directions.

Using the device

Summary of Contents for PFDS 120 A2

Page 3: ...1 2 4 9 10 11 12 3 5 7 6 8 A B C D 13 15 14 16 17 18 22 23 24 25 19 20 21 ...

Page 24: ...24 GB ...

Page 47: ...47 HU ...

Page 48: ...48 HU ...

Page 68: ...68 SI ...

Page 88: ...88 CZ ...

Page 108: ...108 SK ...