17

GB

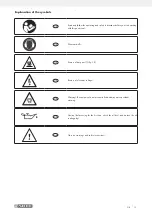

7. Before starting the equipment

• Open the packaging and remove the device carefully.

• Remove the packaging material as well as the packaging

and transport bracing (if available).

• Check that the delivery is complete.

• Check the device and accessory parts for transport damage.

• If possible, store the packaging until the warranty period has

expired.

ATTENTION

The device and packaging materials are not toys!

Children must not be allowed to play with plastic

bags, film and small parts! There is a risk of swal-

lowing and suffocation!

Before you connect the equipment to the mains supply make

sure that the data on the rating plate are identical to the mains

data.

• Check the equipment for damage which may have occurred

in transit. Report any damage immediately to the transport

company which was used to deliver the compressor.

• Install the compressor near the point of consumption.

• Avoid long air lines and supply lines (extension cables).

• Make sure that the intake air is dry and dustfree.

• Do not install the compressor in a damp or wet room.

• The compressor may only be used in suitable rooms (with

good ventilation and an ambient temperature from +5 °C

to 40 °C). There must be no dust, acids, vapors, explosive

gases or inflammable gases in the room.

• The compressor is designed to be used in dry rooms. It is

prohibited to use the compressor in areas where work is con-

ducted with sprayed water.

• The oil level in the compressor pump has to be checked be-

fore putting the equipment into operation.

8. Attachment and operation

m

Important!

You must fully assemble the appliance before us-

ing it for the first time!

You will require the following tools for assembly and installa-

tion:

1x Open-ended wrench size 12 mm

1x Open-ended wrench size 13 mm

1x Open-ended wrench size 14 mm

(not included)

8.1 Fitting the wheels (fig. 4, 5)

• Fit the supplied wheels as shown.

8.2 Fitting the supporting feet (fig. 4, 6)

• Fit the supplied supporting foot as shown.

8.3 Fitting the air filter (fig 7, 8)

• Remove the transportation stop (B) and screw the air filter

(15) to the equipment.

8.4 Changing the transportation cover (A)

(fig. 9, 10)

• Remove the transport lid (A) of the oil filling opening (20).

• Fill the included compressor oil into the crank housing and

insert the included oil sealing plug (16) into the oil filling

opening (20).

8.5 Mains connection

• The compressor is equipped with a mains cable with shock-

proof plug. This can be connected to any 220-240 V~

50 Hz shock-proof socket.

• Before you use the machine, make sure that the mains volt-

age is the same as the operating voltage (see the rating

plate).

• Long supply cables, extensions, cable reels etc. cause a drop

in voltage and can impede motor start-up.

• At low temperatures below +5 °C, sluggishness may make

starting difficult or impossible.

8.6 ON/OFF switch (fig. 2)

• Pull the ON/OFF switch (17) upwards to switch on the com-

pressor. To switch off the compressor, press the ON/OFF

switch down.

8.7 Setting the pressure (fig. 1, 3)

• Use the pressure regulator (5) to set the pressure on the pres-

sure gauge (4).

• The set pressure can be drawn from the quick lock coupling

(3).

• The vessel pressure can be read off the pressure gauge (6).

• The vessel pressure is drawn from the quick lock coupling

(7).

8.8 Setting the pressure switch (fig. 1)

• The pressure switch (2) is set at the factory.

• Cut-in pressure approx. 8 bar

• Cut-out pressure approx. 10 bar.

8.9 Fitting the compressed air hose (fig. 1, 3)

• Use the compressed air hose (14) if you intend to carry out

work at a greater distance from the compressor. To do so,

connect the nipple (H) on the compressed air hose to one

of the quick release couplings (3, 7). Then attach the com-

pressed air tool to the quick-release coupling (I) on the com-

pressed air hose.

9. Electrical connection

The electrical motor installed is connected and

ready for operation. The connection complies with

the applicable VDE and DIN provisions. The cus-

tomer‘s mains connection as well as the extension

cable used must also comply with these regula-

tions.

Important information

In the event of an overloading the motor will switch itself off. Af-

ter a cool-down period (time varies) the motor can be switched

back on again.

Summary of Contents for PKO 270 A5

Page 4: ...14 13 13 max min 6 25 22 9 24 B 7 8 15 A 9 16 20 10 18 11 C E D G 12 C D F...

Page 15: ...11 DE AT CH...

Page 26: ...22...

Page 28: ......

Page 29: ......

Page 30: ......