G B

I E

N I

1 2

facturer of their medical implant

before operating the machine.

Assembly

Caution! Risk of injury!

space in which to work, and that

you do not endanger other peo-

ple.

- Always fasten the device on to

the work surface with screws

thickness in order to maintain

control of the device.

- All covers and protective devices

must be assembled properly be-

fore commissioning.

-

Disconnect the mains plug before

changing the setting on the de-

vice.

Assemble/set workpiece

supports

1. Screw the workpiece supports

(6) on to the device.

6

washer (15), toothed washer (14)

and star nut (7) supplied.

2. Set the workpiece support (6) of

the dry grinding disc with the star

grip nut (7) so that the distance

between the dry grinding wheel

(5) and the workpiece support (6)

must not exceed 2 mm.

Periodically readjust the workpiece

support in order to offset the wear

and tear of the grinding disc (dis-

tance max. 2 mm).

Assemble/adjust spark

protection

1. Screw the spark protection holder

(18) onto the protective hood

(

25). For this, use the adjus-

ting screw (21) including the snap

nut (17).

2. Adjust the spark protection holder

(18) with the aid of the adjusting

the dry grinding wheel (

5)

and the spark arrester holder (18)

must not exceed 2 mm. (see small

image).

Periodically readjust the spark pro-

tection in order to offset the wear

and tear of the grinding disc (dis-

.

.

Despite the spark protection, you

should always wear protective glass-

es when working in order to avoid

eye injuries.

Screw device on to workbench

1. Remove the rubber foot (10) of the

water container.

.

workbench with 4 screws and

.

the device.

-

sembly are not part of the scope of

delivery.

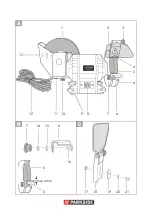

Summary of Contents for PNTS 250 B1

Page 3: ...max 2 mm 1 4 5 4 7 8 9 11 10 12 6 3 2 13 7 6 6 5 14 15 16 17 21 20 18 19 ...

Page 4: ...22 5 23 24 24 4 23 22 5 25 11 13 9 10 13 ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 40: ...40 ...

Page 42: ...13 13a 13a 13c 13d 13b 22 1 26 28 29 27 28 22 1 ...

Page 43: ......