I E

G B

N I

1 3

Fill water into the water tank

.

the drain opening of the water

tank (13).

2. Fill water into the water tank (13)

up to the water level mark

.

Operation

Caution! Risk of injury!

- Always disconnect the plug from

the mains socket before working.

- Use only grinding discs and acces-

sories recommended by the manu-

.

tools and other accessories may

cause risk of injury.

- Only use grinding tools which

bear information about the manu-

facturer, type of binding, dimen-

sion and permitted number of

revolutions.

- Only use grinding discs where

the printed rotational speed is at

least as high as what has been

the device.

- Do not use broken, cracked or oth-

erwise damaged grinding discs.

- Never operate the device without

the visual protection disc.

- Always inspect the grinding disc

before starting the device:

Check the distance between

the spark protection holder and

grinding disc as well as work-

piece support and grinding disc

(distance maximum 2 mm).

-

placed once the spark protection

holder and workpiece support

on the grinding disc do not have

distance of max. 2 mm.

- Switch on the equipment only

when it is safely installed on the

work surface.

Keep your hands away from

the grinding disc when the

device is in operation. Injury

hazard!

Despite the spark protection, you

should always wear protective

glasses when working in order to

avoid eye injuries.

Switching on and off

Ensure that the mains voltage

rating plate.

Connect the equipment to the mains.

.

I

(

8) and the device starts up.

.

0

(

8) and the device switches off.

After switching on the device, wait until the

device has reached its max. speed. Only

then must you start with the grinding.

The disc will continue to

run after the equipment is

switched off. There is a risk

of injury.

Test run:

Before starting work and after each

change of grinding disc, carry out a test

run of at least 60 seconds with no load.

Switch off the equipment immediately if the

disc runs lumpy, substantial vibrations oc-

cur, or abnormal noises are generated.

Summary of Contents for PNTS 250 B1

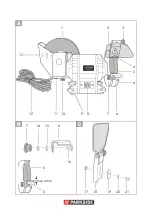

Page 3: ...max 2 mm 1 4 5 4 7 8 9 11 10 12 6 3 2 13 7 6 6 5 14 15 16 17 21 20 18 19 ...

Page 4: ...22 5 23 24 24 4 23 22 5 25 11 13 9 10 13 ...

Page 37: ...37 ...

Page 38: ...38 ...

Page 40: ...40 ...

Page 42: ...13 13a 13a 13c 13d 13b 22 1 26 28 29 27 28 22 1 ...

Page 43: ......