6 GB/IE/CY

Angle grinder PWS 1200

Grinding, roughing, cutting

and polishing

Introduction

Please make sure you familiarise your-

self fully with the way the device works

before you use it for the first time and

that you understand how to handle electrical pow-

er tools correctly. To help you do this please read

the accompanying operating instructions. Keep

these instructions in a safe place. If you pass the

device on to anyone else, please ensure that you

also pass on all the documentation.

Proper use

The device is intended for the dry cutting, rough

grinding and brushing of metal and stone. With ap-

proved types of abrasive consumables and tools

the device can also be used for finish grinding and

polishing. Any other use or modification to the de-

vice shall be considered as improper use and

could give rise to considerable dangers. We will

not accept liability for loss or damage arising from

improper use. The device is not intended for com-

mercial use.

Note:

Slots cut in load-bearing walls must comply

with standard DIN 1053 Part 1 or the regulations

applicable in your country.

These instructions and advice must be observed.

Before you start a task, seek the advice of a com-

petent structural engineer, architect, or the relevant

site management staff.

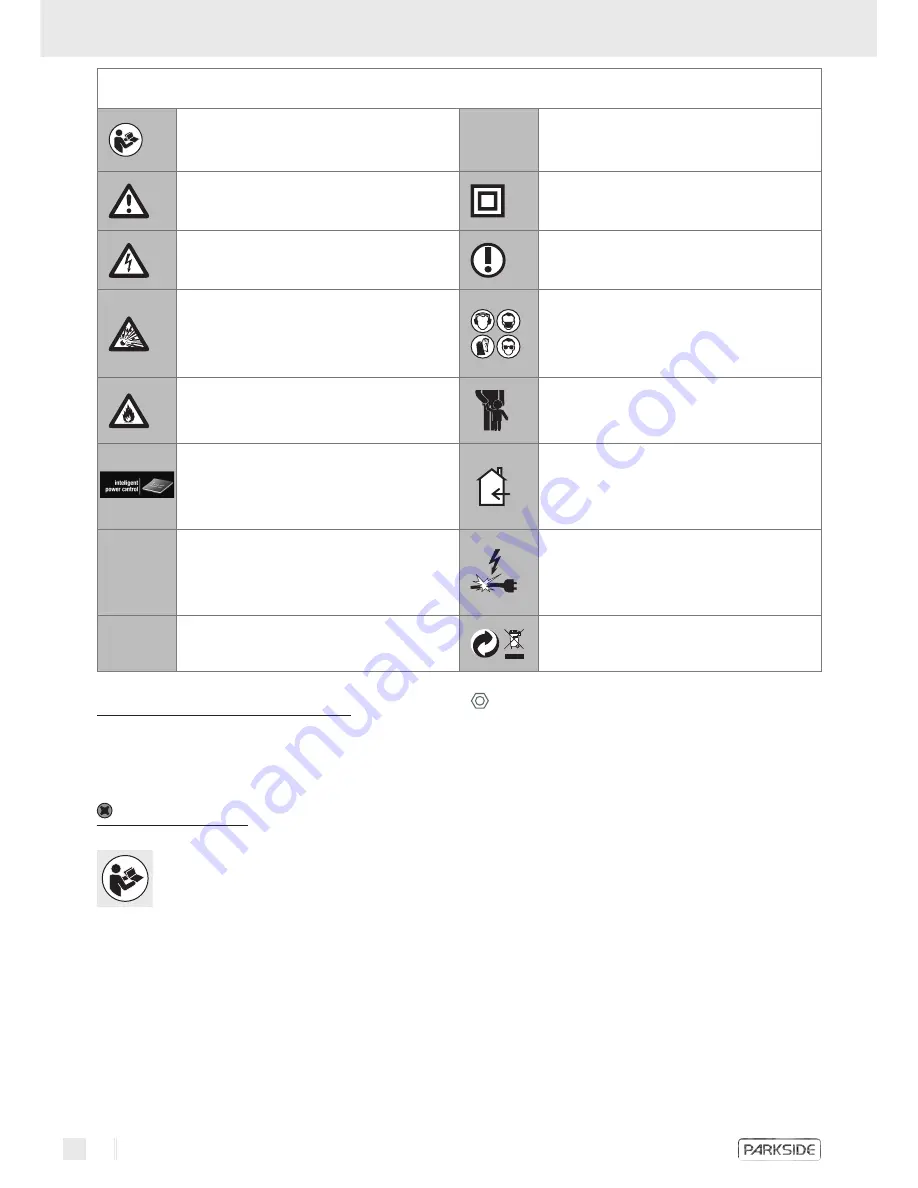

The following pictogrammes / symbols are used in these operating instructions:

Read the operating instructions!

n

0

Rated idle running speed

Always heed warning labels and

safety instructions!

Protection category II power tool;

double insulated

Caution - Danger of electric shock! Hazardous

voltage – danger to life!

Proper procedure and handling.

Explosive material!

Wear hearing protection, dust protection mask,

protective glasses and protective gloves.

Risk of fire!

Keep children and other unauthorised personnel

at a safe distance when using electrical tools.

Soft start to limit heavy transient current surges

Keep the device away from rain or moisture. Wa-

ter entering an electrical device increases the risk

of electric shock.

V~

Volt (AC)

Damaged appliances, power cables and power

plugs mean potentially fatal risks from electric

shock. Regularly check the condition of the appli-

ance, the power cables and the power plugs.

W

Watts (effective power)

Dispose packaging and appliance in an

environmentally-friendly way!

Introduction

Summary of Contents for PWS 1200 - 2

Page 2: ...A B D E 10 1 2 3 4 5 6 7 8 9 C F 11 12 7...

Page 14: ...16...