29

CONNECTION TO THE GAS SUPPLY

Conversion to LPG

LPG jets are included with this appliance. To convert the unit to LPG, replace the jets with a size 7

socket. Ensure that the injector jets are matched with the burner size as per the technical data

table below.

An LPG regulator is not supplied with this appliance and will need to be supplied and fitted by the

authorized installer. The LPG regulator needs to meet all the relevant New Zealand standards.

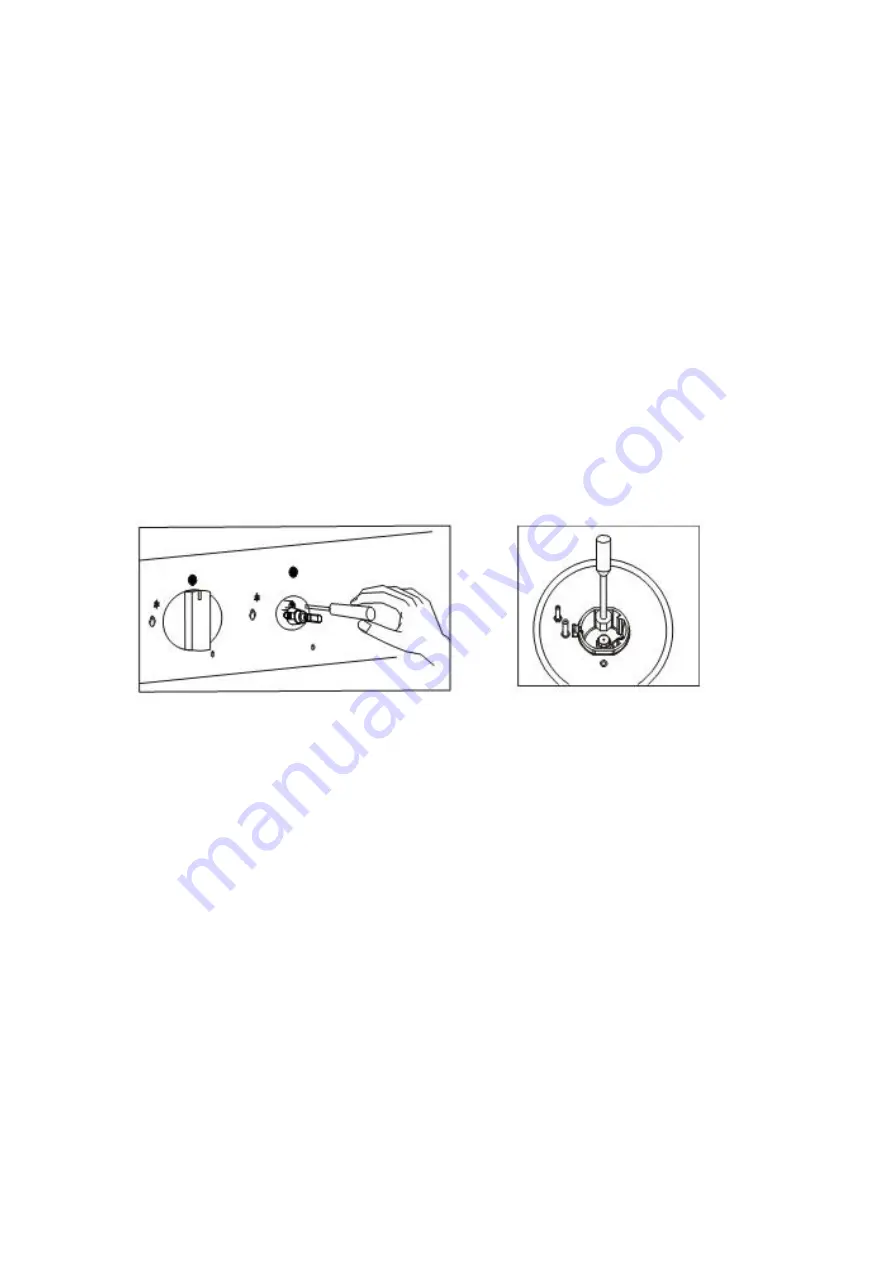

Minimum Flame Setting

The minimum flame adjustment bypass screw is located above left of the gas valve shaft and can

be accessed by removing the control knob. Using a thin blade screwdriver, turn the bypass screw

fully clockwise and then turn it anti clockwise. 1 turn for the wok burner, ½ of a turn for the semi-

rapid burner, and 3/8 of a turn for the auxiliary burners. This should result in a small, stable, flame

that is uniform around the entire burner ring. If not, continue adjusting the bypass screw anti-

clockwise in small increments until the desired low level flame is achieved.

CARALYTIC LINER INSTALLATION

3 Catalytic Liners

NOTE: If your oven does not have catalytic liners and you wish to purchase them, they are

available from your retailer or Parmco.

Operation

The catalytic liners are coated with a specially formulated enamel coating, over a base of regular

enamel. This enamel coating has a rough surface which is also porous. During normal cooking, fats

and other food spatter is partially absorbed into the surface and then oxidised away. This

oxidisation of the fat works best if the oven is set at high temperatures. If you do a lot of lower

temperature baking, say around the normal 180ºC, then the cleaning process may not be

complete. Every now and then you should turn the oven on to maximum temperature for around

one hour to completely remove the soil.