Parry

-British Built for Purpose

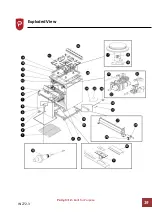

IN272-3

9

Maintenance Instructions

Ensure the appliance is isolated from the power supply before installing, cleaning or

maintaining the appliance.

Maintenance and service must only be undertaken by a qualified electrician.

Parry Catering provides a complete after-sales service by offering the sales of spare parts

directly to customers. Buying spares straight from the manufacturer allows customer to

experience exceptional value and speedy delivery on all spare parts.

For more information on buying spares visit:

www.parry.co.uk/parry-commercial-catering-spares

PLEASE NOTE THE LOW RATE ADJUSTER ON THE UNIT HAS BEEN FACTORY SET AND

SHOULD NOT BE ADJUSTED UNLESS BY A QUALIFIED ENGINEER IN WHICH CASE THE LOW

RATE ADJUSTER SHOULD BE RE-SEALED.

Parry recommends that this unit is serviced at least every 6 months

As part of a full service we recommend the following checks are carried out.

Before any maintenance isolate the appliance from the gas supply

Examine and clean all burner and flame retention ports.

Using a combination of brushes, remove dust and lint from within the primary air

ports venture and burners. Check the burner aeration to ensure it is clear of

debris.

Clean burner injectors ensuring orifices are not enlarged or damaged.

Stiff gas controls can in some instances be greased. Please ensure the correct

type or grease is used.

Check any ignition electrodes and high tension leads where fitted. Clean and

adjust where necessary.

Check Door seal for damage and condition.

Reconnect gas supply and test all disturbed gas connections for gas tightness

using a non-corrosive leak detection fluid.

Check the appliance burner operating pressure, heat input rating or where

necessary both.