-- 8 --

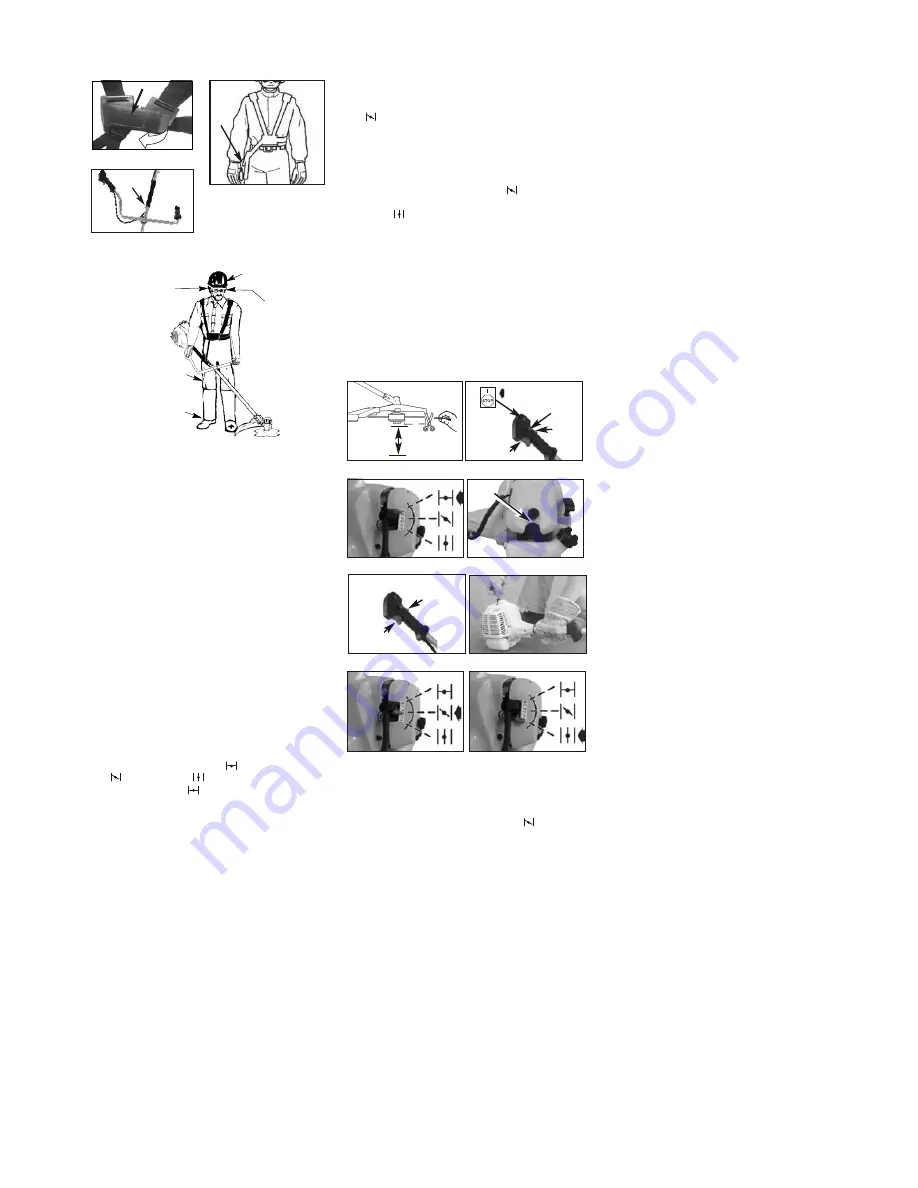

OPERATING POSITION

ALWAYS WEAR:

Hearing

protection

Eye protection

Heavy,

long pants

Boots

Cut from your right to your left.

Safety helmet

When operating unit, clip shoulder strap onto

clamp, stand as shown and check for the

following:

-

Wear eye protection and heavy clothing.

-

Extend your left arm and hold bullhorn

handle with your left hand.

-

Hold throttle grip with your right hand with

finger on throttle trigger.

-

Keep unit below waist level.

-

Keep shoulder strap pad centered on your

left shoulder.

-

Maintain full weight of tool on your left

shoulder.

-

Without bending over, keep the blade or

trimmer head near and parallel to the

ground and not crowded into material

being cut.

STARTING A COLD ENGINE

NOTE:

To minimize load on engine during

starting and warm-up, trim excess cutter line

to 13cm (Fig. 9A).

1. Press ON/OFF switch to the “RUN (I)”

position (Fig.9B).

2. Your unit is designed with a 3 position

choke: FULL CHOKE “ ”, HALF CHOKE

“ ”, and RUN “ ”. Move choke lever to

FULL CHOKE “ ” position (Fig. 9C).

3. Set throttle lock (C): Press the lockout

switch (A) down and then holding trigger

(B) at partially open position, press down

and hold throttle lock (C). Release throttle

trigger (B). Throttle trigger (B) will now

remain in the partially depressed position

(Fig. 9B).

4. Press the primer bulb (A) 10 times (Fig.

9D).

5. Wait 10 sec.

6. A smooth rapid pull is required for a strong

spark. Pull starter rope briskly 6 times

(max) (Fig. 9F)

7. Move choke lever to HALF CHOKE

“ ”position as soon as the engine sounds

as if it is trying to start (Fig. 9G).

8. Pull starter rope again while trigger is in

the full throttle position until engine starts.

(Fig. 9F)

9. Once engine is started, leave the choke

lever in the HALF CHOKE “ ” position for

20 seconds, then move choke lever to

RUN “ ”. If engine does not start, go back

to step 2.

NOTE:

If engine fails to start after repeated

attempts, refer to Troubleshooting section.

NOTE:

Always pull starter rope straight out.

Pulling starter at an angle will cause rope to

rub against the eyelet. This friction will cause

the rope to fray and wear more quickly.

Always hold starter handle when rope

retracts. Never allow rope to snap back from

extended position. This could cause rope to

snag or fray and also damage the starter

assembly.

1. Move switch to the “RUN” position

(Fig.10A).

2. Place choke in HALF CHOKE “ ” position

(Fig. 10B).

3. Grasp throttle handle firmly, squeeze throttle

trigger to FULL position.

4. Pull starter rope briskly until engine starts,

but no more than 6 times. Keep throttle at

FULL position until engine runs smoothly.

NOTE:

Detach the shoulder harness from

the unit before starting engine.

Fig. 9A

Fig. 9B

13cm

For String

Head

0-300mm

For blade

100-400mm

Fig. 9C

Fig. 9D

Fig. 9E

Fig. 9F

Fig. 9G

Fig. 9H

A

Fig. 8A

PUSH

E

Fig. 8B

C

Fig. 8C

D

B

A

B

A

C

WARM ENGINE START

Summary of Contents for B305 CBS

Page 18: ...18 15 50 15m 50ft 3 10...

Page 19: ...19 2 1 T A B C D 1A 2 B E G 15 50 15 50 15 50 15 50 ZU VERMEIDEN...

Page 21: ...21 1 2 3 1 2 3 4 5...

Page 25: ...25 8 8 8 2 4...

Page 26: ...26 12A 1 1 12A...

Page 27: ...27 2 3 4 4 5 2 4 5 6 7 1 2 4 2 4...

Page 28: ...28 1 A B C 16 10 11 9 8...

Page 30: ...30 40 1...