14 –

English

MAINTENANCE

Maintenance

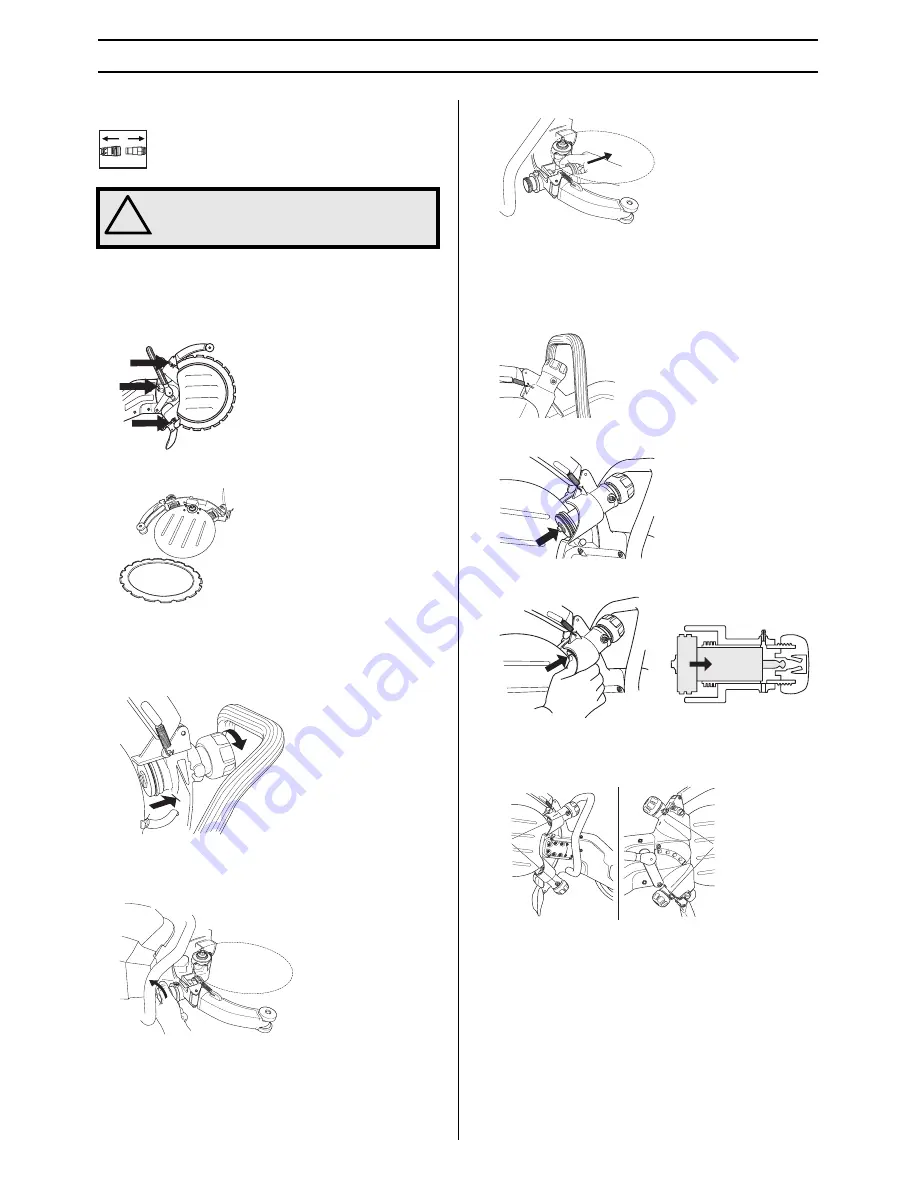

Dismantling the complete guide

roller

•

Remove the support roller cover.

•

Lift off the blade.

•

Unscrew the knob.

First turn the knob a few turns until you feel a resistance.

The guide roller then follows the knob out and stops when

it feels a resistance.

The guide roller is pressed into the knob. In order to loosen

the guide roller, you need to continue turning the knob until it

loosens completely.

•

The guide roller can now be pulled out of the chassis

Assembling the complete guide

roller

•

Screw the knob until it bottoms, and then loosen the knob

2 turns.

•

Insert the guide roller in the chassis

•

Now press the guide roller into the knob.

Lubricate the guide roller’s sleeve using grease. Fit the

grease gun on the grease nipples (A) and pump in grease

until clean grease emerges from the overflow hole (B).

•

Fit the blade. See the heading Fitting the blade.

Important notes:

•

The support rollers do not drive the blade.

•

Incorrect adjustment can result in damage to the blade.

•

If the blade rotates slowly or stops, stop cutting

immediately and trouble shoot.

!

WARNING! Inspection and/or maintenance

should be carried out with the hydraulic

hoses disconnected.

A

B

Summary of Contents for K3600 MKII

Page 21: ......

Page 22: ... z x 6r z x 6r ...

Page 23: ......

Page 24: ... z x 6r 2004 12 22 z x 6r 1088929 26 www partner industrial com ...