12

– English

ASSEMBLY

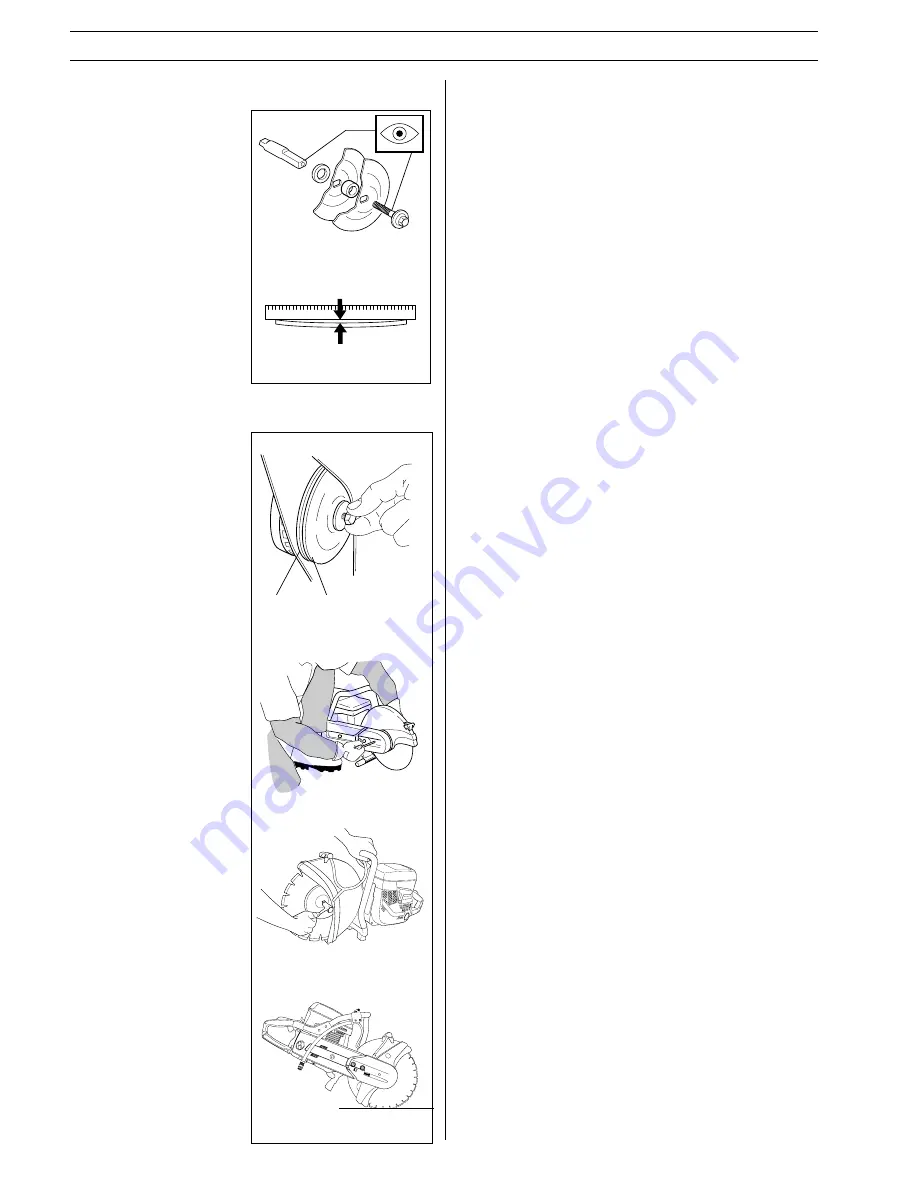

Checking the drive shaft and flanges

• Check that the threads on

the drive shaft are

undamaged.

• Check that the contact

surfaces of the cutting blade

and flanges are flat, run

correctly on the spindle and

are free from foreign

objects.

Do not use flanges that are

twisted, have damaged

edges, untrue or dirty. Do

not use different size

flanges..

Fitting the cutting blade

Partner cutting blades are

manufactured and approved

for freehand cutting. The

paper labels on each side of

the blade are there to

distribute the pressure from

the flange washer and prevent

the blade from slipping.

The blade is placed between

the inner flange hub (A) and

the flange hub (B). The

flange hub is turned so that it

fits on the axle. The cutting

blade is tightened using the

socket spanner

501 69 17-02.

The shaft can be locked using

a screwdriver, steel pin or the

like. This is slid in as far as

possible. The blade is tighte-

ned clockwise.

Tightening torque for the bolt

holding the blade is:

15-25 Nm (130-215 in.lb).

Blade guard

The blade guard should

always be fitted on the

power cutter.

The guard should be adjusted

so that the rear section is

close to the work piece.

Cutting fragments and sparks

are then collected by the

guard and led away from the

user.

A

B

Summary of Contents for K650 ACTIVE III

Page 22: ...22 English xrh 6 ...

Page 23: ...English 23 ...

Page 24: ...108 88 27 26 2002W03 xrh 6 ...