www.parweld.co.uk

www.parweld.co.uk

9

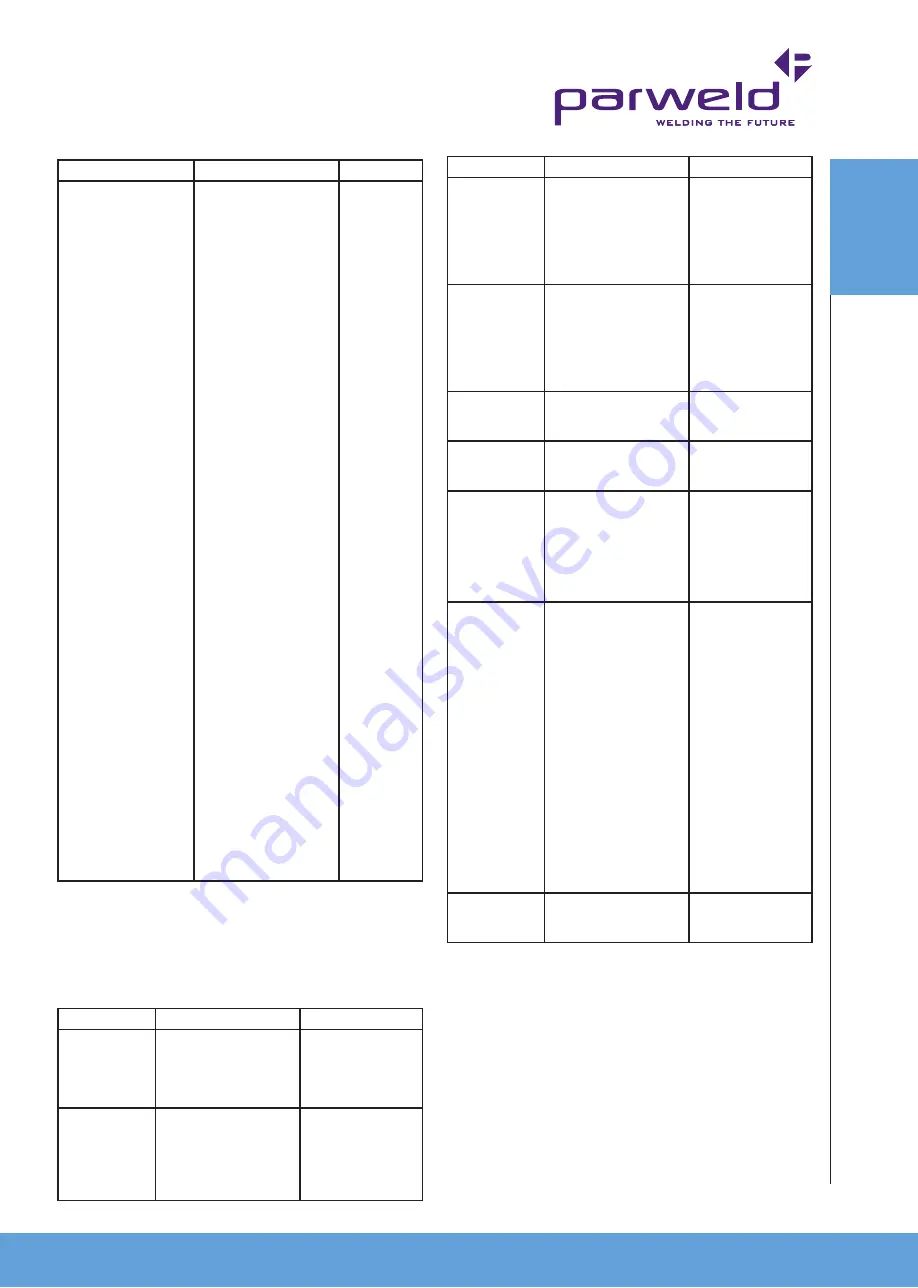

Description

Possible cause

Remedy

Nonmetallic particles

are trapped in the weld

metal (slag inclusion).

(a) Nonmetallic particles

may be trapped in

undercut from previous

run

(b) Joint preparation too

restricted

(c) Irregular deposits

allow slag to be trapped.

(d) Lack of penetration

with slag trapped

beneath weld bead.

(e) Rust or mill scale is

preventing full fusion.

(f) Wrong electrode for

position in which welding

is done.

(a) If bad

undercut

is present,

clean slag

out and

cover with

a run from

a smaller

diameter

electrode.

(b) Allow for

adequate

penetration

and room for

cleaning out

the slag

(c) If very

bad, chip

or grind out

Irregularities

(d) Use

smaller

electrode

with sufficient

current

to give

adequate

penetration.

adequate

penetration.

Use suitable

tools to

remove all

slag from

corners

(f) Use

electrodes

designed

for position

in which

welding

is done,

otherwise

proper

control

of slag is

difficult.

TIG welding problems

Weld quality is dependent on the selection of the correct

consumable, maintenance of equipment and proper welding

technique.

Description

Possible Cause

Remedy

Excessive bead

build up or poor

penetration or

poor fusion at

edges of weld

Welding current is too

low

Increase weld

current and/or faulty

joint preparation

Weld bead too

wide and flat

or undercut at

edges of weld

or excessive

burn through

Welding current is too

high

Decrease weld

current

Description

Possible Cause

Remedy

Weld bead

too small or

insufficient

penetration or

ripples in bead

are widely

spaced apart

Travel speed too fast

Reduce travel speed

Weld bead

too wide or

excessive

bead build up

or excessive

penetration in

butt joint

Travel speed too slow

Increase travel

speed

Uneven leg

length in fillet

joint

Wrong placement of

filler rod

Re-position filler rod

Electrode melts

when arc is

struck

Electrode is connected

to the ‘+’ terminal

Connect the

electrode to the ‘-‘

terminal

Dirty weld pool (a) Electrode

contaminated through

contact with work piece

or filler rod material

(b) Gas contaminated

with air

(a) Clean the elec-

trode by grinding off

the contaminates

(b) Check gas lines

for cuts and loose

fitting or change gas

cylinder

Electrode melts

or oxidizes

when an arc is

struck

(a) No gas flowing to

welding region

(b) Torch is clogged with

dust

(c) Gas hose is cut

(d) Gas passage

contains impurities

(e) Gas regulator is

turned off

(f) Torch valve is turned

off

(g) The electrode is too

small for the welding

current

(a) Check the gas

lines for kinks or

breaks and gas

cylinder contents

(b) Clean torch

(c) Replace gas

hose

(d) Disconnect gas

hose from torch

then raise gas

pressure to blow

out impurities.

(e) Turn on

(f) Turn on

(g) Increase

electrode diameter

or reduce the

welding current

Poor weld finish

Inadequate shielding

gas

Increase gas flow or

check gas line for

gas flow problems

FAUL

T

FINDING