11

RECORD KEEPING

Each organization/company that employs PAS V units should assign a staff member to

be responsible for care and maintenance. A log should be established to record the

checking, calibration and maintenance activities on each unit. Testers using the units

should be required to report any problems with the units to the PAS V staff member who

should record the problems in the log. If a unit is dropped or is damaged in some other

way this should be entered in the log so that the information can be forwarded to the

manufacturer along with the unit for repair. The log will record the life history of the units

and should be carefully maintained since it may be subpoenaed if the use of the PAS V

is challenged.

To ensure that there is a record that these sensitivity checks have been conducted on a

monthly basis, it is necessary to establish a log with a record for each of the PAS V

units employed by the Company or Department. An example of such a record is shown

below.

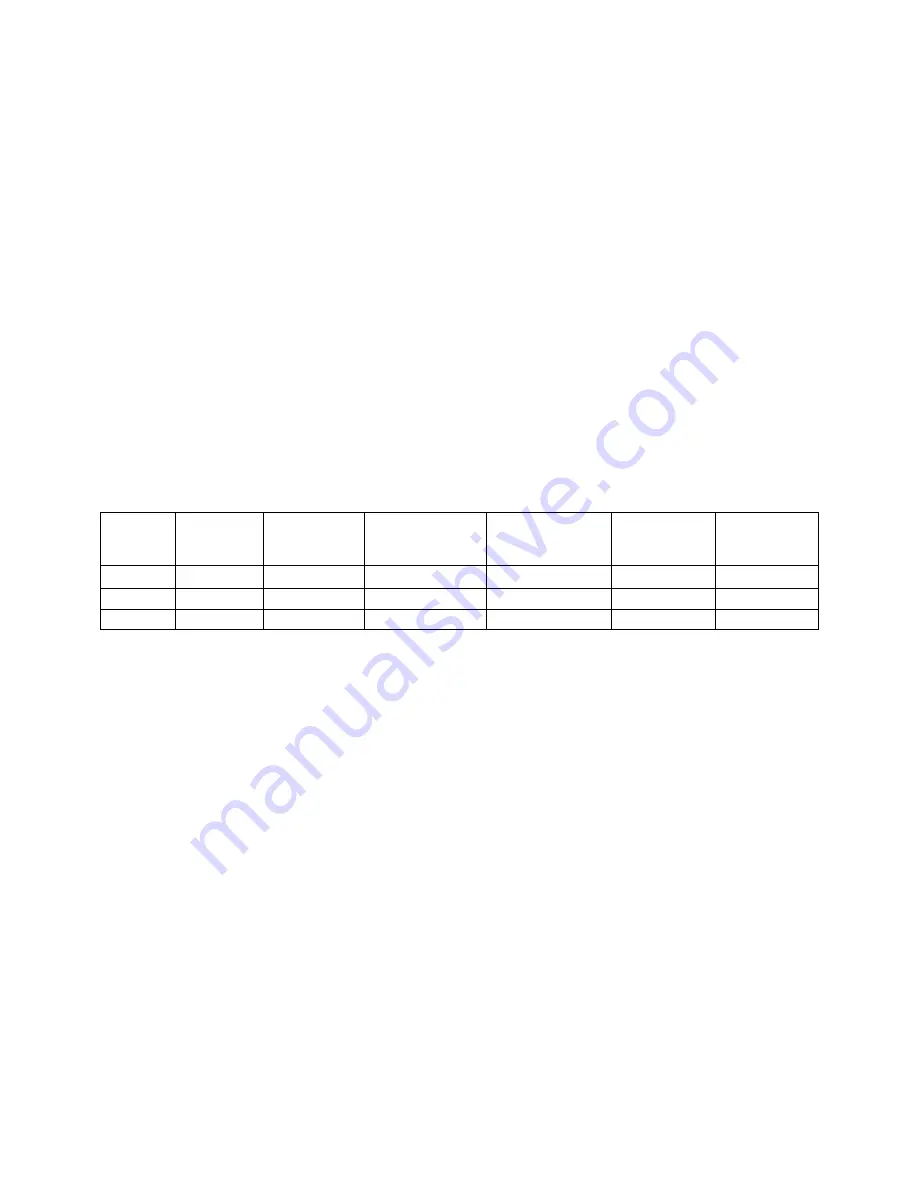

PAS V LOGBOOK

Date

Unit #

Returned

Problem

Reported

Checked By

Action Taken

Date

Returned to

Manufacturer

Date

Returned to

Field

The example shown provides a means for recording any reports from Testers of

problems with the PAS V units or any unusual occurrences such as dropping the

flashlight onto the pavement. The log also provides a brief description of the action

taken to overcome the problem or to examine the unit for damage as a result of a

tester's report. The log will note instances in which the PAS V has been returned to the

manufacturer for service and when it was received and checked upon its return. The

log should also contain a notation recording each month's sensitivity check and the

outcome of that check and also a calibration adjustment if such an adjustment was

necessary.

In addition to monthly sensitivity checks, PAS V units should be checked if they have

received an unusual stress such as being dropped on the pavement. If a PAS V unit

has been sent to the manufacturer and returned following repair, a check should be

made to ensure that the calibration was not affected by the handling during shipping.

Also, perform periodic functional checks with known sources of alcohol to be certain all

functions (e.g., pump) are performing.