In general, operating linkages require virtually

no maintenance. However, in contaminated

atmospheres of where operation under sleet

conditions is common some lubrication at pivot

points may be desirable. The grease used should

be durable even when exposed to the elements,

and should retain its viscosity over a wide

temperature range.

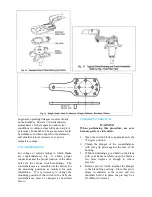

COUNTERBALANCE

For voltage or current ratings in which blades

are counterbalanced, Fig. 11 shows proper

connections and the proper location of the drain

holes for the various switch mountings. The

counterbalances are assembled at the factory for

the mounting positions as required for each

installation. If it is necessary to change the

mounting position of the switch in the field, the

counterbalance must be changed, as described

below.

UPRIGHT TO VERTICAL

WARNING

When performing this procedure, use care

because parts are in tension.

1.

Open the switch blade to approximately the

75 degree position.

2.

Clamp the plunger of the counterbalance

with vise grip pliers against the face of the

housing.

3.

While maintaining a good hold on the blade

with your hand, carefully open the blade a

few more degrees or enough to relieve

pressure.

4.

Remove pin (A) which attaches the plunger

to the blade hinge casting. Since this pin is

larger in diameter at the center and two

shoulders hold it in place, the pin may be a

bit difficult to remove.

Summary of Contents for TTR6

Page 1: ...IB TTR6 B May 2012 ...

Page 6: ...5 P a g e ...