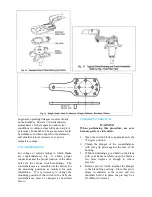

CRANKS

The two switch poles that are not connected to

the offset bearing normally use a single crank,

similar to Fig. 15. The switch pole that is

connected to the offset bearing (drive phase)

uses either a solid double crank, or a two piece

adjustable crank, as shown in Fig. 5. The offset

bearing used a two piece adjustable radius crank

plus a separate stop crank with multiple

mounting holes for angular adjustment. Figs. 16

and 17.

INSTRUCTIONS FOR SPECIAL SWITCHES

For switches specifically designed to operate

under abnormal ice conditions, it is important

that they be adjusted to assure the switch blade

(on a closing operation) exerts force on the jaw

stop.

FORCE VALUES

Switch Voltage

Force on Stop

8.25 thru 169 kV

80 lbs.

242 thru 840kV

40 lbs.

The blade force adjustment should be made after

the switch instillation is complete, as described

previously in this instruction manual, except for

the corona rings.

The blade force adjustment is made as follows:

Start with the three-pole switch in a position so

that the blade end contacts are at least 1 foot

from the stationary contact fingers. Using the

manual operator, and observing one switch pole,

lower the blade into the finger contact assembly

and continue to close the switch to the point

where it rests on the stop and there is

approximately 1/8” clearance between the blade

end contact and the stationary contact fingers on

each side, see Fig. 19. This is the point at which

the blade force is to be measured. It is important

that the 1/8” clearance is obtained as the switch

is being operated toward the closed position as

described and never as the switch is being

opened. This would cause an improper

adjustment.

Using a force gauge, measure the force exerted

by the blade on the jaw stop by either pushing

the blade up from below and noting the lbs. at

which the blade is lifted off the jaw stop, or by

putting a wire loop around the blade and lifting

it with the gauge and noting the lbs. required.

The place on the blade at which the force is

measured should be just outside the finger

contact assembly, see Fig. 18. If the force

required is not proper, an adjustment must be

made at the hinge end of the switch. To make

the necessary adjustment, move the switch blade

to a convenient point near the full open position

and remove crank pin (B), Fig. 18, then move

and twist blade or forked link (D) to disengage

clevis (C) from crank.

If the force measured was too high, turn the

clevis (C), 1/2 turn into the forked link (D). But

if the force measured was too low, turn the

clevis (C) 1/2 turn out of the forked link and re-

connect the clevis. Check the threads on the

clevis, some switches have right hand threads

and others have left hand threads. Close the

switch to the point previously described and

again measure properly, another adjustment

must be made. Repeat the procedure previously

described. After one switch pole is satisfactorily

adjusted, the other two poles should then be

adjusted in the same manner.

Table 1

Lubrication Guide for Outdoor Switch Components

Part Name

Type Lubricants

Recommended

Amount

Applied

Qty. Req’d. for

(6) Three-pole

Switches

Jaw Fingers

NO-OX-ID Grade “A”

Special or Mobil 28

Grease

Medium

Coat

Blade Ends

NO-OX-ID Grade “A”

Special or Mobil 28

Grease

Medium

Coat

(1) Quart

Pins On current

carrying parts Mobil 28 Grease or DC-4

*

Pins On control

parts

Mobil 28 Grease or DC-4 Light Coat

(1) Quart

Bearing Areas

On control parts Mobil 28 Grease or DC-4

Medium

Coat

Terminal

Connections

NO-OX-ID Grade “A”

Special or NO 2 EJC

Heavy

Coat

(1) Quart

13 |

P a g e

Summary of Contents for TTR6

Page 1: ...IB TTR6 B May 2012 ...

Page 6: ...5 P a g e ...