Also, Fig. 4 shows blade contact high on the

right and low on the left. The reverse is also

acceptable, high on the left and low on the right.

It is common to have both situations on one

three-pole switch. In fact, after all three poles

have been adjusted in the open position, and

then closed, you may find that one pole will be

high on the right, one fairly level and one high

on the left. This is

due to many variables and tolerances plus the

free play or clearance in pin connections of all

the switches and control parts.

Variance in contact angle is not significant

because no reduction in contact pressure occurs

until the blade exceeds ±8˚ above the horizontal.

Blade Height in Jaw

—In Fig. 3, dimension (D)

can vary from 0” to 5/8” with the switch in the

closed position. It is not usually possible to get

this dimension to be equal on all three poles of a

three-pole switch. If it’s necessary to adjust this

dimension, remove connecting pin (A) and turn

clevis (B) in or out ½ turn then reconnect and try

switch. Turning the clevis in will move the

blade away from the blade stop. Conversely,

turning the clevis out will move the blade closer

to the blade stop.

Open Blade Stop

—

On switches, there are stops

for the blade in the open position, as shown at

(C), Fig. 3. Some of these stops have flat

washers that can be relocated to raise or lower

this stop, while the voltage rated switches use

treaded bolts with lock nuts. In either case,

raising the stop surface (C) will reduce blade

opening angle; lowering the stop surface (C) will

increase the blade opening angle. After each

pole has been adjusted, set the open and closed

stop bolts of each rotating insulator.

6 |

P a g e

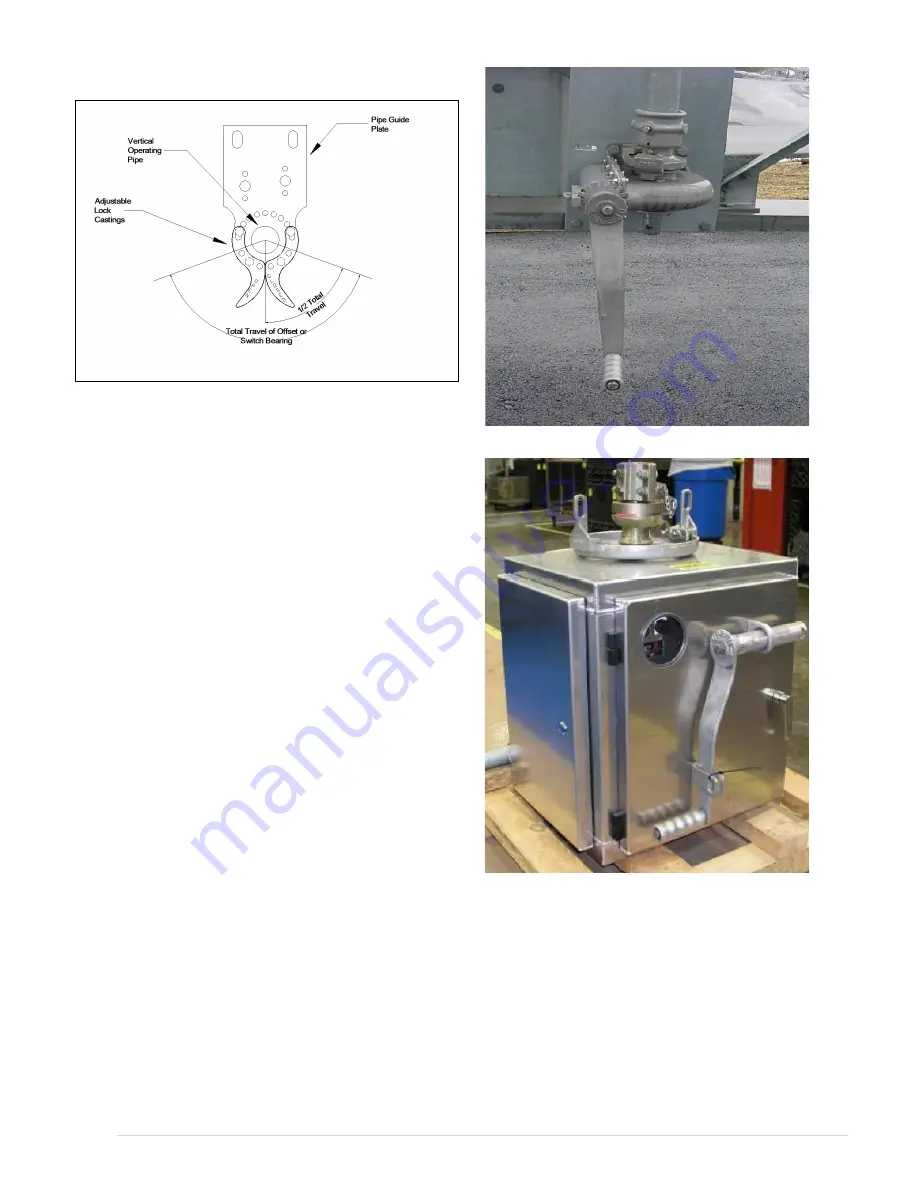

Fig. 9 MO-10 Motor Operator

Fig. 8 Geared Mechanism

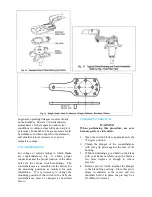

Fig 9. Operating Handle Lock Plate

Summary of Contents for TTR6

Page 1: ...IB TTR6 B May 2012 ...

Page 6: ...5 P a g e ...