18

19

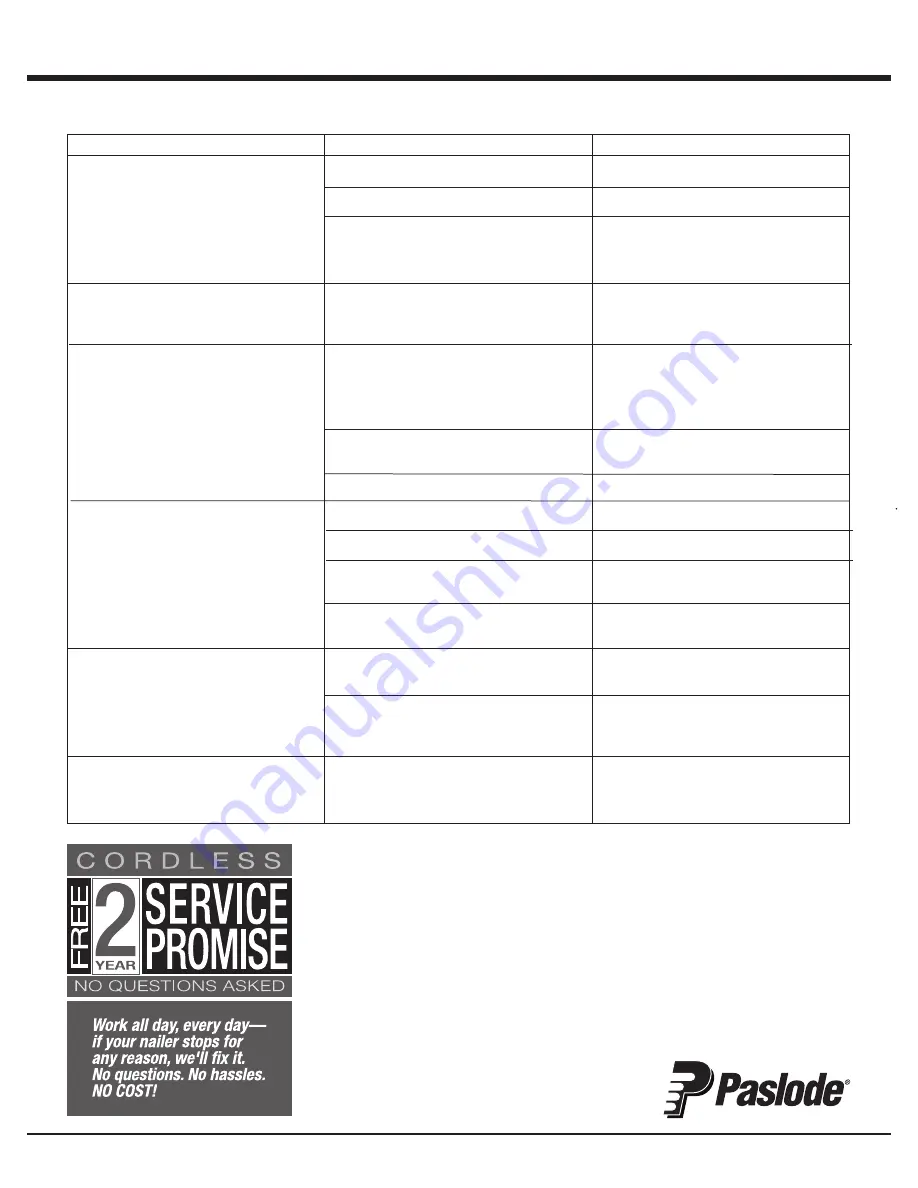

Tool operates properly, but fasteners do not

drive fully.

Tool operates properly, but fasteners are

sometimes over-driven, and sometimes

under-driven.

Tool operates, but no fastener is driven.

Tool operates erratically or appears to be

losing power - tool indicator light is green.

Nail Hole Locating Probe requires adjustment.

Fuel cell is low.

There may be loss of seal in combustion

chamber.

Nail Hole Locating Probe is not adjusted

properly for the type of material being fastened.

Wrong fasteners being used.

Follower not properly engaged behind fastener

strip.

Jammed fastener.

Fuel cell is low or too cold.

Spark plug wire is loose.

Air filter is dirty, causing tool to overheat.

Tool is dirty.

Adjust the Probe.

Check fuel cell and replace as required.

Press Nail Hole Locating Probe against

workpiece for one minute. Pull trigger. If

fastener does not drive, there is a leak that

requires service.

Adjust the Probe. Readjust

as required when material density or thick-

ness of material being fastened changes.

Use only fasteners meeting Paslode

®

specifications. Check Fasteners and Ap-

plications section for fastener types and

sizes recommended for use in Paslode

Cordless tool.

Position follower behind fastener strip and

engage strip.

Clear jam.

Check fuel cell.

Check spark plug wire.

Remove air filter and clean. Use soap and

water to remove stubborn debris.

Clean tool.

Normal Stage of Operation

SYMPTOM

POSSIBLE PROBLEMS

SERVICE

Tool operated and drove fasteners, but

driver blade did not return to up position.

Combustion chamber does not drop after

tool cycles.

Built-up dirt and debris on driver blade or in

nose bore.

Tool is dirty.

Nail Hole Locating Probe is bent, or is dirty.

Clean driver blade and nose bore with

degreaser cleaner.

Clean tool.

Clean track or replace the Probe.

Troubleshooting

Still not working? Here are more options:

•

Your nailer may qualify for our Cordless 2 Year

Service Promise. Visit paslode.com for more

information or call us at 1-800-222-6990.

•

Keep your cordless nailer in top form. Visit paslode.com

and watch our Cleaning and Maintenance videos.