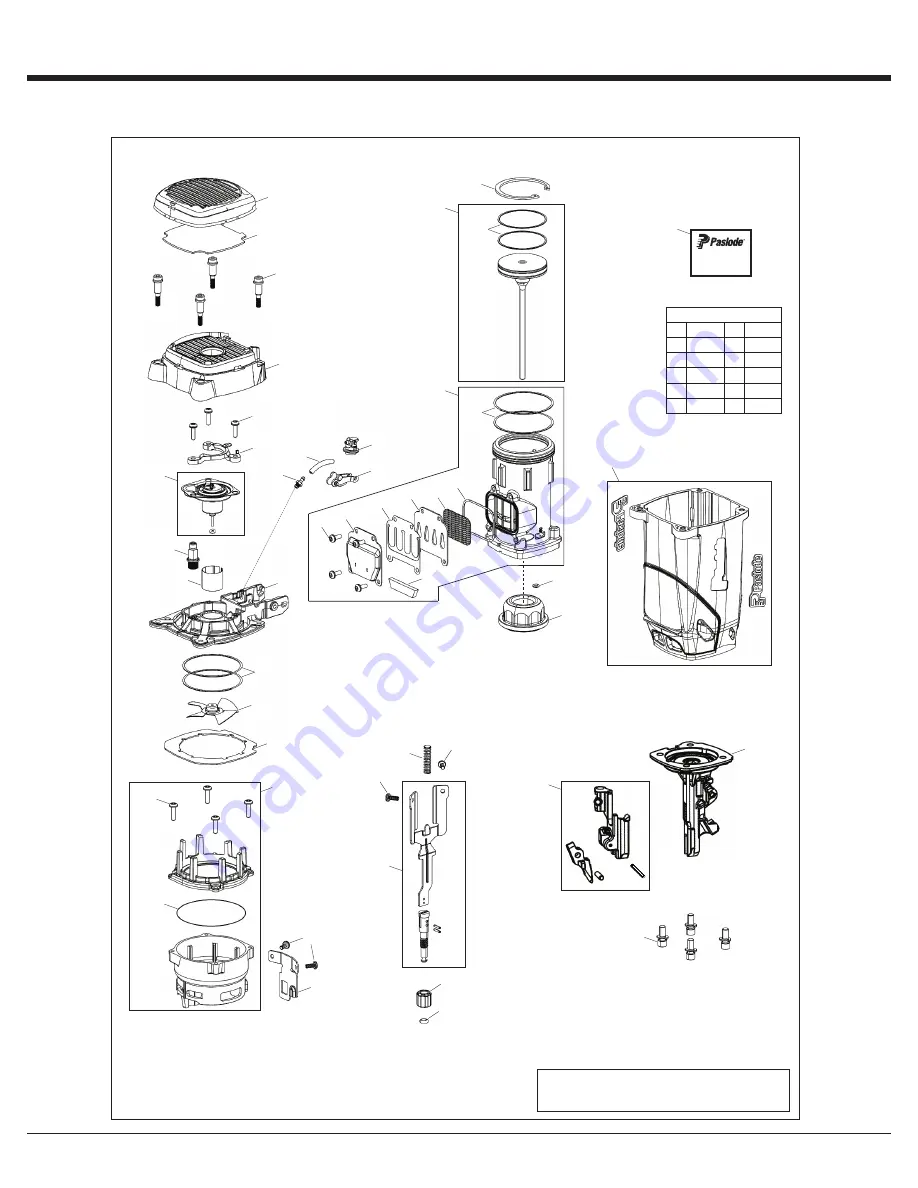

All parts sold as single items unless described as a pack, set or

forms part of an assembly (multiple items defined within a box).

A part with no item number is only available in an assembly.

1

2

3

4

5

6

12

7

8

11

13

14

15

16

17

23

24

25

15

26

30

28

27

31 32

33

29

34

35

40

85

SERVICE KIT

010031

Service Kit Item

Loctite

®

242

43

Torque Values (in/lb)

Item Torque Item Torque

3

55-60 19 35-40

5

30-35 21 30-35

8

20-25 27 30-35

10 15-20 43 155-165

16

8-10

9

10

21

22

18

19

20

41

42

36

37

21

1

21

1

38

39

•

•

•

•

•

•

•

•

•

•

•

Part No. 906200

Model CF150-PP

Schematics (cont.)

21