Operator's Manual

DS 350 / 1334

© PAT

Rev. D 04/12/02 CSH

190072_d.DOC

6

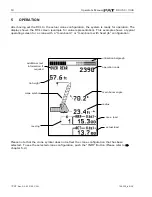

signification of the individual elements.

Rated Capacity Limit Light

The red RATED CAPACITY LIMIT LIGHT (2) warns the operator that a rated

load condition has been reached. It lights up when the load on the crane

reaches the crane load capacity. The audible alarm also sounds when this

condition has been reached.

The following crane movements will be stopped concurrently:

−

hoist up

−

telescope out

−

boom down

Rated Capacity Prewarning Light

The yellow RATED CAPACITY PRE-WARNING LIGHT (3) will light up when the

load on the crane reaches the defined prewarning area, thus indicating that an

overload condition is approaching.

This means for the operator to continue his crane operation with extreme

caution.

Alarm Light “Anti-2-Block”

The red “Anti Two-Block Alarm Light” (4) lights up when the anti-two-block

limit switch contacts open, indicating that a two-blocking condition is

approaching. At the same time the audible alarm will sound.

The following crane movements will be stopped subsequently: hoist up and

boom down (depending on your machine).

By-Pass Key Warning Light

The red BY-PASS WARNING LIGHT (5) flashes to indicate that the kick-out

function of the A2B / RCL system is deactivated.

Button and Control Light “Alarm Stop”

This ALARM STOP BUTTON (6) allows the audible alarm to be silenced for

approximately 15 seconds by pressing this button. Reference

⇒

“Audible

Alarm” (12).

Button and Control Light “Tare”

The button “TARE” (7) is used to indicate the “Net load” on the LC Display (1).

Net load is the present load, less lifting tackle and hook block. The Tare Button

(7) has to be activated

before

lifting.