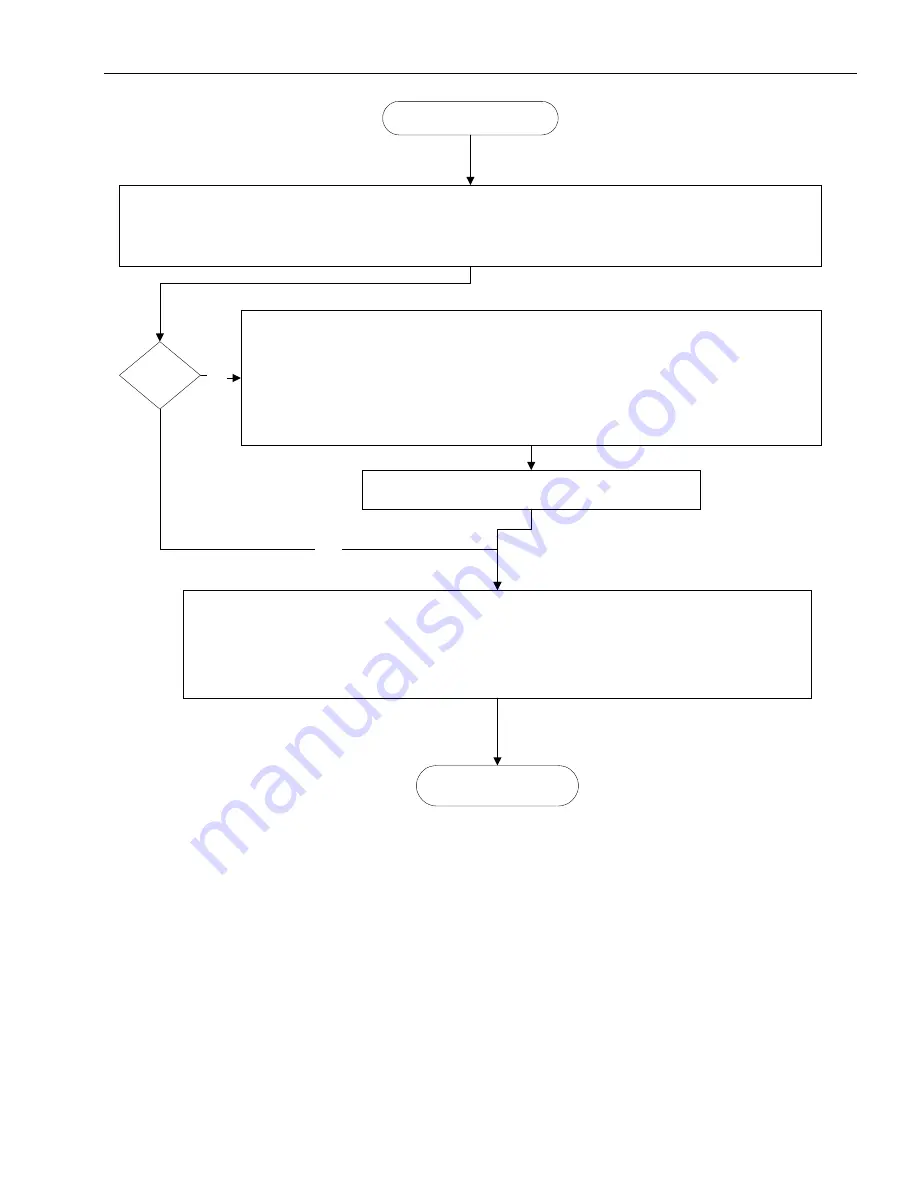

Load Reading

© PAT

Rev. - 12/18/00 // CSH.

190118_-.DOC

19

PREVIOUS PAGE

No Fault in cable or wiring.

Check force transducer for any visual damages.

Complete the force transducer calibration in operator's and calibration manual. If force

transducer can not be adjusted replace force transducer.

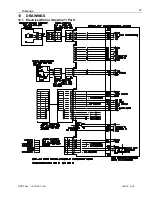

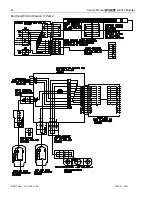

Refer to Procedure 5 and Drawing 1 or 7.

YES

END

Check linerider for any visual damages and check continuity in:

!

force transducer cable assembly (A to A, B to C, C to B, note the wiring of the

connector)

!

junction box (5 socket to 14 pin: A to D, B to C, and C to A)

!

cable reel, and cable assembly 14 pass connectors B to B, C to C, and D to D.

Refer to Drawing 1.

NO

Check power supply to force transducer by unplugging the cable assembly from the force transducer.

Measure voltage at the cable connection between A (+12/24v) and C (ground) at the connector.

Refer to Drawing 1 in Section 12.

Correct?