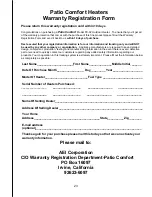

11

g into the

n

.

is

ly process. Do not attach

ead to post at this time.

r

he

tions so you

annot incorrectly attach the post.

inserting

r

6)

to the

well

ets before you insert post

to base assembly

.

. Insert the fuel feed line with the head attached

tom

This may be most

asily accomplished if the heater is assembled

LOCKING WASHERS AND FLAT

).

he

inst

mber to help.

Make

ure that the decorative cover is in a stable

exiting

e

e

se

5. Insert the 3/8” brass male flared fittin

inlet fitting at the base of the heater head.

Do not use any Teflon tape or pipe compound

on this or any other brass-to-brass connectio

The brass fitting will self-seal. Securely tighten

using two wrenches in a clockwise direction (but do

not over-tighten) this fitting. Be sure to check th

connection with a soapy solution before using

heater. Never use a match or flame to check for

gas leaks. We will leak test the system completely

in Step #13 of the assemb

h

6. Slide the heater

post over the fuel

feed line. The post

will only fit one way.

The end of the post

that connects to the

heater head has fou

holes drilled about

1/2” below the top

portion of the post.

The part of the post

that will attach to the

base portion has

four holes drilled

approximately 1 ½”

from the end of t

post. (

See #5)

Again, the holes in the post and the holes in the

head and base are in different posi

c

7. Before

the post

assembly/fuel

feedline into the

base portion slide

the post collar up

the post with the

end that has fou

notches facing

downward toward

the base.

(See #

The collar adds

extra rigidity

post to base

assembly as

as hides the fasteners from view

. Be sure the

cylinder decorative cover is placed over the

base assembly brack

in

8

through the post.

9. Now carefully insert and position the post

with fuel line into the base socket assembly.

Please be sure that the portion of the fuel line

with 3/8” brass flare fitting that exits the bot

portion of the post passes through the hole in

the post support plate.

e

on its’ side.

(See # 8)

10.

Using four of the Phillips machine screws

and only four flat washers (DO NOT USE

WASHERS AT

THIS

CONNECTION

If you use both

flat and locking

washers at this

connection t

sleeve will not

be able to slide

over the

fasteners.

11. Carefully lift up the decorative cover. The

decorative cover when tilted will rest on the post

support brackets and will be held by resting aga

the fasteners.

(See # 7)

If you have trouble doing

this ask a friend or family me

s

#5

#7

position as it could cause injury if it slides off

the post support

bracket.

12. Remove the

second protective

plastic cap from the

3/8” flared fitting

the bottom of the post.

Gently engage the

fitting at the end of th

hose/regulator

assembly onto end of

the fuel feed line being

careful not to cross-

thread the fitting.

(Se

# 8)

The swivel fitting

at the end of the ho

and regulator assembly should go on easily. Hand-

tighten the fitting at the hose assembly before using

wrenches. Tighten the 3/8” female flare at the end

of the hose to the fuel line inlet fitting going through

the hole in the base plate with two wrenches.

#8

#6