22 | P a g e

PATON

®

PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

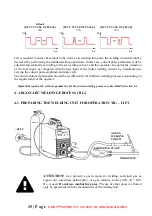

4.7. LINEAR DECREASE OF WELDING CURRENT

This function is designed for smooth welding of a welding crater, which can be formed in the welding

pool due to electromagnetic blow forces generated by the welding arc. The crater so formed can be a

source of future welding defects. By default, the period

[TIME DOWN ARC]

of linear decrease of

welding current is 3.0 s and can be varied by the operator at his option.

The procedure for changing the values of the operational parameters of the welding unit is described in

Section 6.1.

4.8. WELDING CRATER CURRENT

This function is designed for decreasing the welding current at the end of welding. The decrease of

welding current is required for welding a crater at the end of the weld. To activate the function for the

TIG-4T welding process, press and hold the button of the welding torch for the second time. By

default, the

[POST CRATER ARC]

crater welding current is 20 A.

The procedure for changing the values of the operational parameters of the welding unit is described in

Section 6.1.

4.9. WELDING AT PULSE WELDING CURRENT

This function is designed to simplify the control of a welding process in various spatial welding

positions, excluding a flat welding position. This function is also used in welding nonferrous metals.

When this function is activated, the application of pulse welding current improves the mixing of

molten metals in the weld area and causes forced action on the transfer of molten metal drops into the

welding pool, therefore the stability of the weld formation and the stability of the welding process are

improved. The pulse welding current in the manual arc welding process affects the weld parameters

similar to the movement of the operator hand in manual arc welding process, specifically at hard-to-

reach places.

The proper adjustment of the welding process parameters in the welding at pulse welding current has a

direct effect on the weld quality, specifically reduces weld metal porosity and decreases the graininess

of the weld metal. As a result of the improved weld quality, the weld strength increases.

To activate this function, it is necessary to set the following three operational parameters of the

welding process: current pulse amplitude

[POWER OF PULSE]

, current pulse frequency

[FREQUENCY

OF PULSE]

, and duty cycle

[FREQUENCY OF PULSE]

. By default, the current pulse amplitude is 0

[OFF],

that is, the function is switched off, the current pulse frequency is 10.0 Hz, and the duty cycle

is 50%. To activate the function, set the current pulse amplitude

[POWER OF PULSE]

higher than 0.

The current pulse amplitude should be set in percentage of the welding current specified for the

welding process.

Example

:

Welding is to be performed with welding nonconsumable tungsten electrode

Ф

2.0 mm

in diameter. The set welding current is 100 A. The current pulse

[POWER OF PULSE]

amplitude is 30%. The current pulse frequency

[FREQUENCY OF PULSE]

is 10.0 Hz

(default value). The duty cycle

[DUTY CYCLE OF PULSE]

is 50% (default value).

Result:

The result is the following: the welding current pulse amplitude will be in the range of

70 … 130 A, the current pulse frequency will be 10.0 Hz, and the current pulse length

will be equal to the length of an interval between pulses. If the duty cycle is not equal to

50%, the current pulses will be nonsymmetrical relative to the intervals between pulses,

but the average welding current value will be equal to the set welding current value of

100 A. As a result, the average heat input to the weld will not change.