25 | P a g e

PATON

®

PSI PRO 270 / 350 400 V DC MIG/MAG TIG/MMA

21.

By using the button

(8)

we can adjust the wire feeder speed and the value of additional

functions of the wire feeder.

22.

The device is ready for use.

Enjoy Your work.

If required, perform the additional functions specified for the semiautomatic arc welding process (see Section

6.1).

Do not forget to provide the supply of protective gas, in order to check it in the channel of the holder,

the button

(9)

is intended. If you have no experience in setting optimal gas pressure for welding the

specific parts, first set the pressure so that it exceeds the expected optimal pressure by about 0.2 MPa.

In this mode, the increased pressure will not affect the welding process and will only induce the

increased consumption of protective gas. In the future, fulfill the general instructions concerning

semiautomatic arc welding. For welding with any electrode wire diameter in the range of 0.6 … 1.2

mm, set the medium electrode wire feed velocity of 7 … 10 m/min and the medium welding voltage of

about 19 V. Notwithstanding that these parameters are not optimal, they are sufficient for welding if

the stable and uniform wire feed is provided. In order to achieve better results, set the optimal welding

voltage, by buttons

(1)

, and electrode wire feed velocity by adjusting potentiometer

(8)

according to

the general instructions on semiautomatic arc welding. Remember that the parameters to be set are

different for different welding processes.

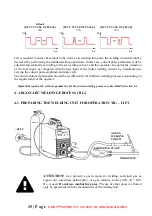

5.2. OPERATIONAL CYCLE OF THE WELDING PROCESS - MIG / MAG

The procedure for changing the values of the operational parameters of the welding unit is described in

Section 6.1.

t (s)

t (s)

t (s)

I (A)