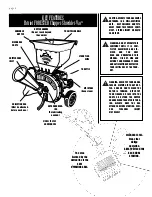

page 10

15-ft. V

ac Kit Assembly

(Optional)

The optional vacuum kit, 15 feet long and 4” in

diameter, is used to vacuum and grind leaves,

pine straw and other loose organic waste. The

kit is sold separately; instructions are provided

here and with the kit for your convenience.

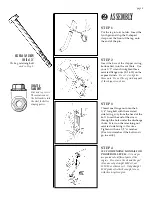

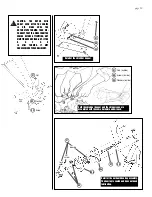

FIRST

Insert two 1.25”-20 carriage bolts from inside the

nozzle and through the holes in the handle.

Fasten with the two 1/4”-20 serrated flange nuts

provided using a 7/16” wrench.

SECOND

Push one end of the hose firmly into the nozzle.

The nozzle has what is called a “regressive” fit.

Turn the nozzle a few times to adjust the angle

of the nozzle.

THIRD*

Thread the other end of the hose into the adap-

tor about three inches. You may need to tug it

through from the other side.

FOURTH*

When you want to use the vac, snap the adaptor

into the hopper

befor

e you turn on the engine

. The

adaptor only fits with the DANGER decal on

your right as you stand behind the machine.

FIFTH & LAST*

Snap the cone cover over the chipper cone. This

seals off all air flow for maximum vacuuming

power.

*

Patented design featur

ed in this step.