CA

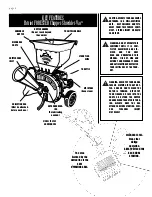

UTION: DO NOT LET GO OF BULKY

WASTE AND LET IT BOUNCE AROUND

IN THE HOPPERS. IT MAY DAMAGE

THE MACHINE OR BE EJECTED

TOWARD THE OPERATOR OR

BYSTANDERS AND CAUSE INJURY.

“QUICK-FEED” PRUN-

INGS DOWN THE

LEFT SIDE OF THE

SHREDDER WITH A

LOOSE, OPEN GRIP.

▲

!

page 12

V

acuuming

VACUUM (15-ft. kit optional)

HP

CAPACITY

TYPE OF DISCHARGE

Dry to wet leaves,

5, 6, 8 & 10

Loose waste

Fine mulch (leaves),

pine straw, sawdust,

some fingerling shreds.

grass clippings.

V

ACUUMING TIPS

•

Keep the hose straight or slightly curved along the ground.

• Allow nozzle to hover over the waste, rather than sticking it into the pile.

• If the vacuum loses power, there may be a clog in the nozzle or in the

throat of the shredder hopper. Lift the hose over your head and shake it.

You may need to shut down, unplug the adaptor and unclog the

shredder’s throat.

• Don’t let the hose come in contact with the muffler. The muffler can get

hot enough to melt it.

❹

HO

W IT WORKS

Direct-Bagging

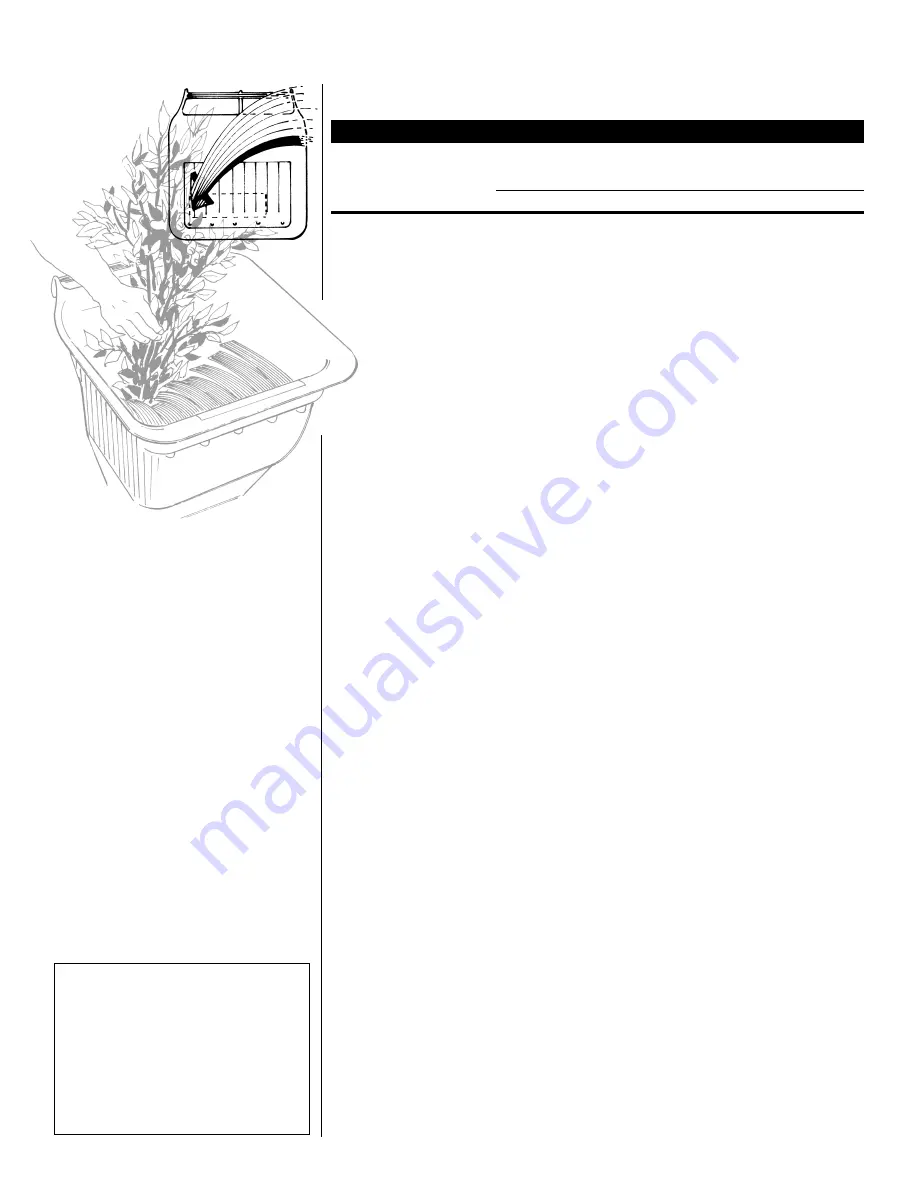

The chipper

-shredder-vac must be operated with the bag in place. The bag

holds over two bushels, but emptying it often is a good habit. If it overfills,

debris may back up into the discharge chute and stall the engine—just like a

lawn mower does when it’s bag gets too full.

Gr

eat will be the temptation

...but do not begin to r

emove the bag until the

engine is shut off and the rotor has stopped.

Chipping

W

aste fed down the chipper cone produces uniform, coin-sized chips. Two

sharp knives, mounted on the rotor, pass by the cone’s solid base at more than

3750 RPM, slicing the end of the branch into little chips.

The angle of the knives draws branches in as they are cut. Eventually, the

knives become dull. They must be removed and re-sharpened. Replace the

knives when their cutting surface nears one-eighth inch from the knives’

mounting holes.

Shredding

The shr

edder uses six Y-shaped hammers and the built-in vacuum to pull

waste into the grinder housing. The shredding hammers attached to the rotor

grab onto thicker debris. Material is ground and shredded until it is small

enough to be pulled into the fan chamber and discharged into the bag.

The rotor spins clockwise (as you stand behind the machine). The

hammers swing freely on shafts a full 360°. If material is too heavy to shred on

the first strike, they swing out of the way. The Y-forks do the shredding and

pulling. (Technically speaking, green debris is said to be “shredded”; drier,

leafier debris is “ground”.) Hammers eventually wear down and can be

replaced or simply reversed.

V

acuuming

The four blade vacuum draws air into the housings thr

ough the shredder hop-

per and chipper cone. To take full advantage of this air flow system, the

optional vacuum kit snaps into the hopper for a 15’ reach around the machine.