✔

Keep your balance. Don’t overr

each. Watch your step around the cord.

✔

Disconnect the machine when it is not in use. Make sur

e the switch

is moved to OFF before plugging the unit back in.

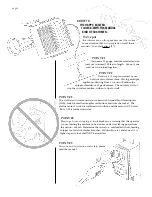

Some Don’

ts

▲

Do not attempt even a

minor

clean-out of the hoppers or dischar

ge chute

while the rotor is turning!

▲

Do not continue operating the chipper

-shredder-vac if unusual vibration

or noise occurs. Shut down, inspect for damage, replace or repair parts as

needed and check fasteners for tightness before resuming work. If there

are still problems, take it to a PATRIOT Service Center.

▲

Do not allow childr

en to operate this equipment.

▲

Do not operate this equipment ar

ound children, pets or bystanders.

▲

Don’t operate in slick, wet or congested ar

eas.

▲

Don’t operate on paved or gravelled surfaces.

▲

Don’t permit materials to build up in the collection bag. The chips and

shreds may clog the discharge chute, resulting in stalling or even a kick

back of material out of the hoppers.

▲

Do not put your hands or any other part of your body or clothing inside

the hoppers or discharge chute—or near any opening to moving parts!

▲

Don’t transport the machine with the motor r

unning.

▲

Don’t dump waste in the shr

edder using a trash or nylon bag. It may get

caught by the vacuum or the grinder, causing damage or injury.

Long-T

erm Care & Storage

Stor

e the chipper-shredder-vac out of

reach of children. Do not leave it

plugged in.

The steel parts are finished with

a baked-on powder coating. This

type of paint process is more durable

and more environmentally friendly

than sprayed-on paints.

Wash your machine—unplugged,

please—with a garden hose. Soap

won’t hurt it either.

❷

ASSEMBL

Y

First & Foremost

The parts you must assemble ar

e packed in the cardboard base beneath your

chipper-shredder-vac. These parts

must be assembled

befor

e any attempt is

made to start the motor!

The collection bag—which is to be used at all times—must be put on

before each operation.

Step by Step

If anything is dented, bent or badly scratched, now is the time to notify your

place of purchase. The box should include:

• the

chipper-shr

edder-vac

, with factory-installed motor

, wheels and

shredder hopper;

•

collection bag

;

• the

chipper cone

with

chipper cone base.

• the

fr

ont leg

(it’s supposed to be bent!); and,

• a

bag of hardwar

e,

containing:

(5) serrated flange nuts, 5/16-18

(1) hex-headed cap screw, 5/16-18 x 3.25”

(1) Allen wrench, 5/32” (for hopper maintenance only)

(1) Allen wrench, 3/16” (for chipper knife maintenance only)

The lynch pin for the leg is already on the unit. The vacuum kit is not

included with your unit. It is packaged and sold separately.

You will need one 1/2” box end wrench for assembly.

W

ARNING: DO NOT OPERATE

THIS EQUIPMENT UNTIL (1)

IT IS COMPLETELY ASSEM-

BLED AND SERVICED, AND

(2) YOU READ AND UNDER-

STAND THIS MANUAL. (3)

SIGN AND RETURN YOUR

WARRANTY REGISTRATION

CARD WITHIN 10 DAYS AND

TELL US WHAT YOU THINK

OF THE PATRIOT.

▲

!

page 7