March 2016

Standards Council, NFPA, 1 Batterymarch Park Quincy, MA 02169-7471.

NFPA Standard #96 Vapor Removal from Cooking Equipment, latest edition, available from the National Fire Protection

Association, Batterymarch Park, Quincy, MA. In the commonwealth of Massachusetts all gas appliances vented through

a ventilation hood or exhaust system with a damper or with a power means of exhaust shall comply with 248 CMR.

In Canada:

Local codes:

CAN/CSA-B149.1 Natural Gas Installation (latest edition).

CAN/CSA-B149.2 Propane Installation Code (latest edition), available from the Canadian Gas Association 178 Rexdale

Blvd., Etobicoke, Ontario Canada M9W 1R3.

The installer of this unit should be aware of state, county or local code for connecting this equipment to determine if an

external regulator is required

Clearance and positioning around the equipment:

This equipment must be installed adjacent to non-combustible surfaces only with a minimum spacing of 6” from all

sides. This equipment must be a distance of 6” from other equipment. The equipment must have the 4” legs installed

and be placed on a non-combustible surface.

Air Supply and ventilation:

The area in front and around the equipment must be kept clear to avoid any obstruction of the

fl

ow of combustion and

ventilation air.

Adequate clearance must be maintained at all times in front of and at the sides of the equipment for servicing and

proper ventilation.

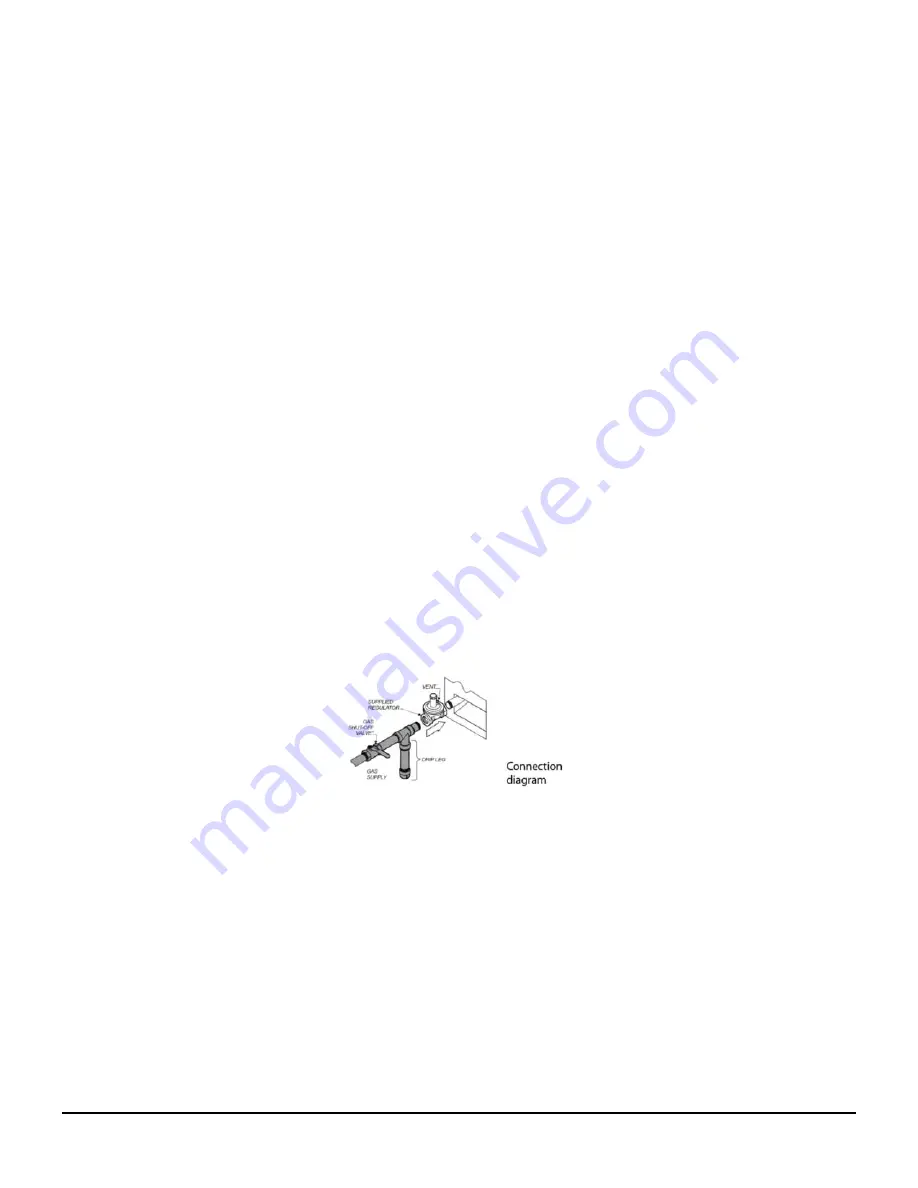

Pressure Regulator:

All commercial cooking equipment must have a pressure regulator on the incoming service line for safe and ef

fi

cient

operation. The regulator provided for this equipment is adaptable for both Natural gas and LP gas.

Regulator speci

fi

cations: ¾” NPT inlet and outlet, factory adjusted for 4” WC Natural Gas standard and may be

converted by quali

fi

ed personnel to be used for Propane at 10” WC.

GAS CONVERSION:

Conversion from Natural Gas to Liquid Propane (LP) or vice versa may only be performed by the factory or its authorized

service agent. In case of troubleshooting, ensure the correct ori

fi

ce sizes of the tips have been provided.

Ori

fi

ce size is marked on the tip.

Natural Gas Ori

fi

ce is #36

Liquid Propane Gas Ori

fi

ce is #50

Gas Connection:

The appliance comes

fi

tted with a ¾” NPT (National Pipe Thread) male adapter for connection to the

pressure regulator.

Maintenance:

A quali

fi

ed service company should check the unit for safe and ef

fi

cient operation on an annual basis.

Contact the factory representative or local service company to perform maintenance and repairs.