P-K Storm

TM

Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: October 2, 2019

Released: October 2, 2019

Patterson-Kelley 2019

All Rights Reserved.

2691000099 P-K Storm Installation and Owners

Manual.docx

Page 42

3.9 Pre-Start Checklist

Before attempting to start the boiler, make sure the following items

have been completed.

Inspect the gas train, blower, ignition electrode, and boiler in general

to be sure there was no damage during shipment or installation.

Flue gas from the boiler is properly vented.

Gas connection has been made, pressure tested for leakage and the

line purged of air. Make sure all required vents have been installed.

Water connections are complete, and the boiler and system have

been filled and purged of air.

The boiler is connected to the correct electrical power source listed

on the nameplate, a disconnect having adequate overload protection is

required.

Combustion air openings are not obstructed in any way and have

adequate capacity.

The boiler is placed the proper distance from any combustible walls.

Relief valves have been piped to an acceptable drain at a safe point

of discharge.

Condensate piping is properly connected.

Verify system water quality is within specifications.

3.10 Safety Checks

The following checks of safety systems must be made before putting

the boiler into normal operation. Before firing the boiler refer to

Section

for information on the use of the controls, lighting, and

shut-down procedures.

Ignition Safety System Test

Test the ignition system safety shutdown as follows:

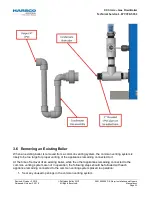

1. Cycle the boiler on by generating a heat request. (The

method for this will depend on your boiler configuration.)

2. During the pre-purge cycle (before ignition), smoothly close

the downstream manual isolation valve (inside the boiler

cabinet) to reduce the gas flow.

3. Closing the manual isolation valve will prevent a successful

ignition, and the NURO will display either:

109:

“Ignition Failed”

110:

“Ignition Failure Occurred”

These alarms indicate an ignition failure and the lockout will remain until the control is reset. After

completing this test, turn the boiler off, open the downstream manual isolation valve, then turn the boiler

back on.

Low Water Cut-Out Test

The boiler is furnished with a probe-type low water cut-

out. The probe is installed near the boiler’s

outlet in order to detect the presence of water at the highest possible location in the boiler and is

connected to the low water cut-out circuit board by a single wire. The low water cut-out circuit board is

located inside the boi

ler’s front door, toward the bottom left of the control panel and is identified with a

label.

Never attempt to operate

a boiler that has failed to

pass all the safety

checks described below.

Operating a boiler that

has failed a safety check

could result in injury.

Bypassing safety

mechanisms will result

in unsafe boiler

operation which could

result in injury or death.

After checking controls

by manual adjustment,

make sure they are

always reset to their

proper settings.

The user should become

thoroughly familiar with the

operation of the boiler and

controls before attempting to

make any adjustments.

Changing parameters

requires an understanding of

the parameters and the

functionality of the boiler.

The boiler may not function

properly if parameters are

changed from the factory

values.