P-K Storm

TM

Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: October 2, 2019

Released: October 2, 2019

Patterson-Kelley 2019

All Rights Reserved.

2691000099 P-K Storm Installation and Owners

Manual.docx

Page 57

5. Take a sample of the system fluid and verify the water quality complies with the standard

– Water Quality Standards Quality Standards for Hydronic Boilers

6. Inspect and clean the condensate system and check for leaks. If a condensate neutralization kit

is present, open the lid and inspect the media. If they are absent or have been significantly

worn away, replace them with new media.

7. Examine the venting system. Refer to the vent manufacturer's instructions for requirements in

addition to those listed below.

a. Check all joints and pipe connections for tightness.

b. Check pipe for corrosion or deterioration. If any piping needs replacing, do so

immediately.

c. Inspect and clean any screens in the vent terminal.

8. Qualified service personnel should thoroughly inspect the heating system and correct any

problems prior to re-starting the boiler.

9. Perform combustion analysis and readjust as necessary according to the Combustion Setup and

Adjustment combustion settings table.

Refer

to

It is recommended that a copy of this report is filed for future reference.

10. Perform a leak test of the gas valve in accordance with the

gas valve manufacturer’s

instructions.

5.2 Cleaning the Combustion Chamber

Patterson-Kelley recommends cleaning the combustion chamber once annually using the following

procedure:

1. Lockout/Tagout gas supply to the boiler.

2. Lockout/Tagout electrical power to the boiler.

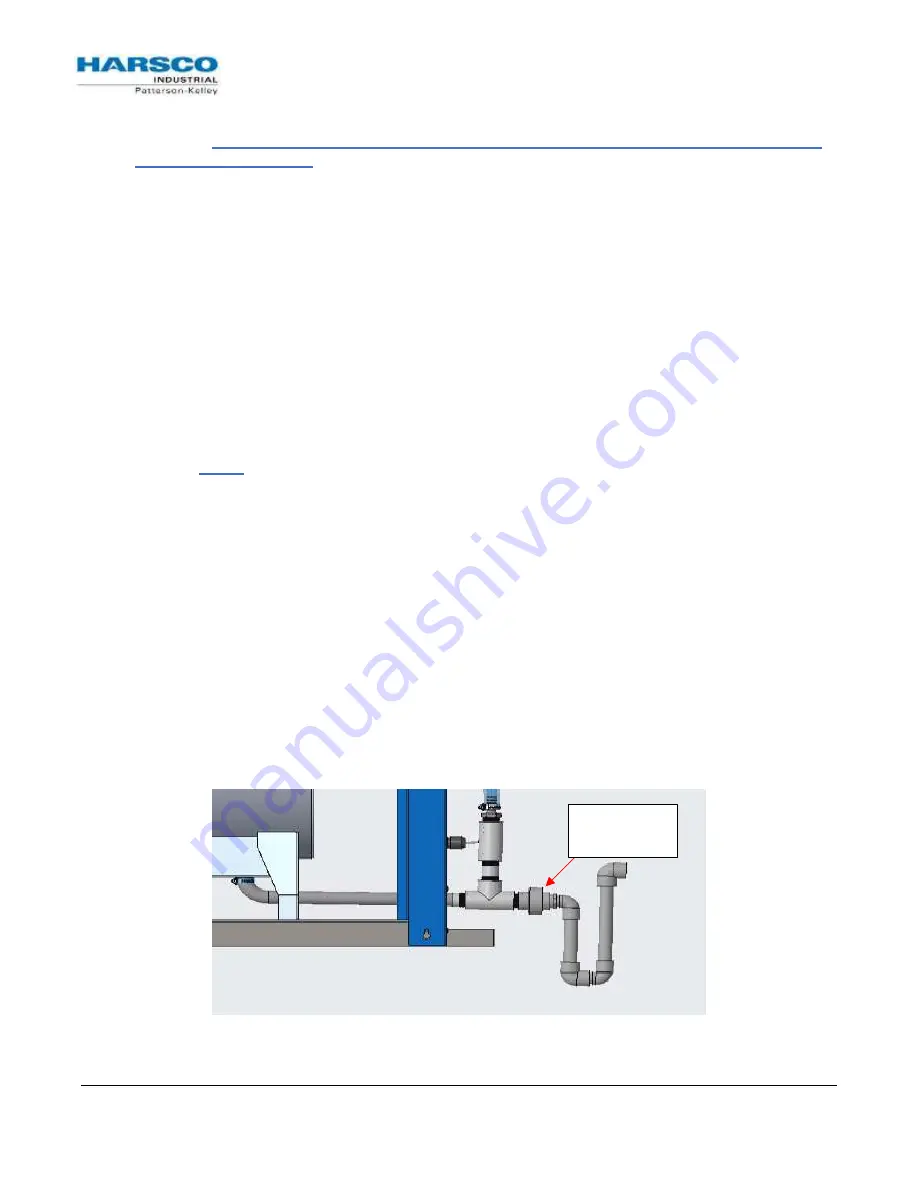

3. Disconnect the condensate piping and install a temporary drain hose into the condensate

trap/drain. Run the open end of this hose to a nearby floor drain.

4. Make sure the surrounding area is free of obstacles.

Disconnect

at Union