P-K Storm

TM

Gas Fired Boiler

Technical Service 1.877.728.5351

Revised: October 2, 2019

Released: October 2, 2019

Patterson-Kelley 2019

All Rights Reserved.

2691000099 P-K Storm Installation and Owners

Manual.docx

Page 22

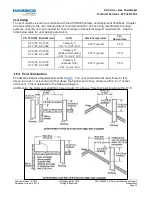

Sizing the Combustion Air Intake Ductwork

The combustion air flow rate requirements per boiler model are summarized in

. When sizing the

combustion air intake ductwork, the pressure drop through this ductwork

MUST NOT

exceed 0.22”

W.C. as described in the table below:

P-K STORM

™

Boiler Model

Flue Vent Category

Maximum Allowable

Pressure Drop

through Combustion

Air Ductwork

Allowable Vent

Pressure

ST-1250, ST-1500,

ST-1750, ST-2000

II

0.22” W.C.

-

0.01” W.C. to

-

0.05” W.C.

ST-1250, ST-1500,

ST-1750, ST-2000

IV

0.22” W.C.

+0.01” W.C. to

+0.22” W.C.

NOTE:

If the combustion air intake ductwork and the exhaust vent terminate on the same wall of

the building, they

must

utilize the same type of termination fitting.

NOTE:

Patterson-Kelley recommends including a motorized combustion air damper in each

appliance’s air intake ductwork. Refer to

more information.

Motorized Combustion Air Dampers

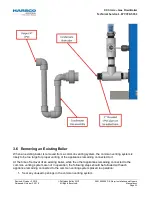

Patterson-Kelley recommends, and most

installation codes require, the use of motorized

combustion air dampers with end limit switches

installed in the combustion air intake ductwork

upstream of each appliance. This damper isolates

the combustion air supply when the appliance is in

standby. Once the appliance receives a call for

heat, the motorized combustion air damper opens,

and the end limit switch must close before the

appliance can proceed to ignition. Patterson-

Kelley offers motorized combustion air dampers

with built-in end limits switches for sale, which are

summarized in the table below:

Table of Recommended Motorized Combustion Air Dampers

Combustion Air Ductwork

Size

Normally-Closed

Motorized Damper

A

B

C

D

8

”

10-0490-6944

8

”

8

”

11

”

2.38

”

10

”

10-0490-6945

10

”

10

”

13

”

3.38

”

12”

10-0490-6946

12”

12”

15”

4.38”

These normally-closed motorized combustion air dampers operate on 120 VAC and feature a built in

end limit switch which must be wired to the appliance

s’ Air Damper Interlock circuit. Upon a call for

heat, the boiler

’s Air Damper Relay energizes, which drives the damper motor open. Once the damper

reaches the fully-open position, the end limit switch makes contact and closes the Air Damper Interlock

circuit, allowing the appliance to proceed to ignition. The diagram on the next page shows the wiring

necessary to install the normally-closed motorized damper.