pattersonfan.com

800.768.3985

19

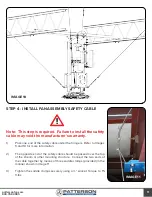

STEP 4 - MOUNT THE REMOTE KEYPAD & CONNECT TO THE VFD

CAUTION: It is vitally important that the remote keypad is ALWAYS mounted outside the blade

radius of the fan. This is especially important for the daisy chaining configuration (see page 25). The

daisy chaining process requires access to the keypad while the fan is in motion.

1)

Once a desired location is found, affix

the remote keypad to the wall using

the mounting pads attached to the

keypad enclosure.

2) Run the Cat 6 cable up to the

fan-mounted VFD via the shortest

possible path. If possible, avoid

lighting and other noise-producing

electrical equipment. Running the

cable inside conduit is optional.

3)

Pass the Cat 6 cable through the strain

relief and then into the bottom of the

drive. Connect to the cable coupler

and secure to the inside of the drive as

shown in Image 19.

DO NOT

connect the cable directly to the receptacle on the face of the VFD. Be

sure to tighten the strain relief on the bottom of the VFD.

4)

Replace the cover of the VFD and screw down securely.

STEP 5 - CONNECT THE VFD TO A FIRE SUPPRESSION SYSTEM

(OPTIONAL)

WARNING: There should be no voltage on the fire suppression system cable. Placing voltage

on the VFD terminal block will destroy the unit and void all manufacturers’ warranties.

CAUTION: DO NOT connect Patterson High-5 fans to the fans of another company for purposes

of fire suppression. A separate line must be run for Patterson fans ONLY.

CAUTION: If the drive will not be connected to any fire suppression system, the factory installed

jumper across 9 & 15 MUST remain in place.

1)

Remove the factory installed jumper between terminals 9 and 15. The terminal block is located at the

bottom of the ACS355. For more information, refer to Image 18 on page 18.

2)

Connect the fire suppression system wires to terminals 9 and 15. Again, the fire system cable will

leave the drive enclosure out of one of the holes on the bottom, using a strain relief

(not provided)

.

3)

Drive is now wired to shut down upon activation of any fire suppression signal.

THIS COMPLETES THE ELECTRICAL

INSTALLATION OF YOUR HIGH-5 FAN.

Cord Strain

Relief

Cable Coupler

IMAGE 19