4

SECTION V

MAINTENANCE

1.

There should be no mechanical seal leakage except for a brief break in period. Mechanical seals

should be replaced if they are leaking

3.

Refer to the motor manufacturer s instructions for periodic maintenance requirements.

4.

Check that electrical control equipment contacts are in good condition and clean.

5.

Bearing relubrication requirements refer

to the motor manufacturer s instructions.

Do not

overlubricate the bearings.. Such action will cause bearings to overheat.

6.

Refer to the General Pump Inspection and Maintenance Schedule for best results.

General Pump Inspection and Maintenance Schedule

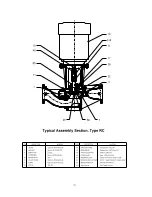

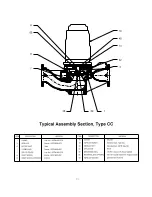

VIL Pumps, Types RC, CC, and CS

Excludes motors, VFD s, and controls.

Contact Patterson Pump Company if assistance is needed to determine the inspection and service

requirements for a specific pump.

Inspect (

) or service ( ) at the indicated calendar

time or run time interval whichever comes first

Routinely

Monthly

2000

hours

or 3

months

4000

hours

or 6

months

8000

hours

or 12

months

Unusual noise

Unusual vibration

Unusual temperature

Leaks in pump or piping

Pressure gauge readings

Visual inspection of equipment general condition

Anytime a pump is opened, inspect the running

clearances and restore them to original specifications if

the running clearances have doubled.

Anytime a pump is opened, inspect the impeller for

corrosion or excessive wear.

Mechanical seal (should be no leakage)

Drain lines are working properly

C o u p l i n g i n t e g r i t y ( T y p e R C o n l y )

Operate the pump

A d d g r e a s e t o m o t o r a n t i - f r i c t i o n b e a r i n g s

( m a i n t a i n r e c o r d s )

Refer to motor manufacturer s instructions.

Perform a comparative field test (flow, pressures, and

power) with calibrated instruments. Restore internal

running clearances if results are unsatisfactory (install

new wear rings).

P e r f o r m a c o m p a r a t i v e v i b r a t i o n t e s t

I n s p e c t s l e e v e . R e p l a c e i f w o r n .