11

Maintenance by the operator

Maintenance of the ventilation device and plant by the operator is limited to the periodic change of the filters and

cleaning of the supply and extract air valves. The filter must be checked every 3 months and changed if necessary,

however, at least every 6 months.

In this context, also check other filters available inside the ventilation plant and change them if necessary. A

replacement or cleaning of the filter mats at the extract air valves (e.g. bathroom, kitchen, W.C.s) should be carried

out every 2 – 3 months or at your own discretion when checking the degree of soiling.

If maintenance work is not carried out regularly, this impairs the functioning of the comfort

ventilation in the long term!

Replacement of the filter

The plant must not be operated without filter. During filter replacement and maintenance work, the

ventilation device must be switched off!

Two high-quality original filters of the manufacturer are installed inside the CLIMOS. After the corresponding

message of the control panel or after visualisation of a programmed digital output signal, the filters in the CLIMOS

shall be checked. In order to do so, proceed as follows:

1. Switch the device to standby mode or disconnect it from the power supply.

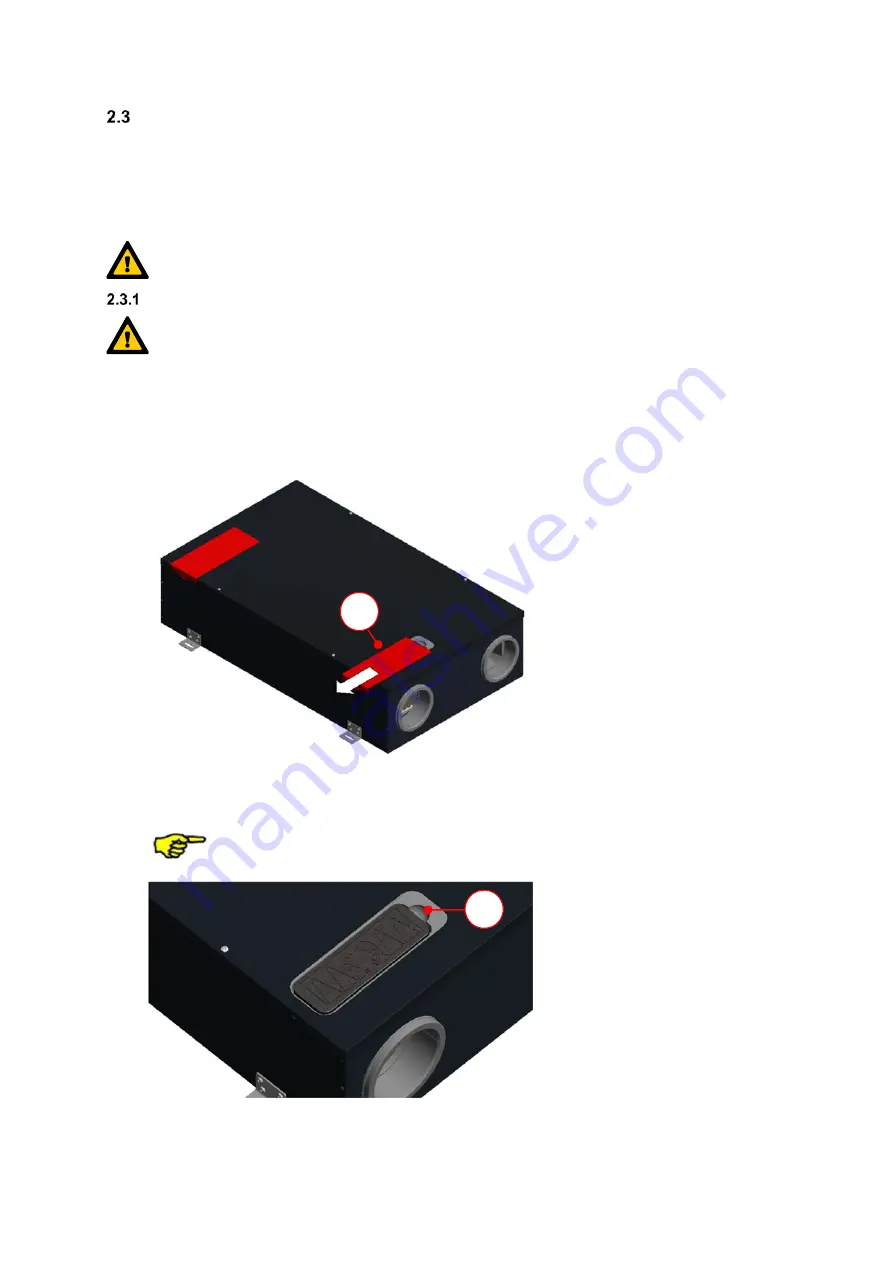

2. If applicable, pull the red design filter cover

A

out of the casing cover’s holder.

3. Grasp into the recessed grip

B

of the filter compartment.

Perhaps the EPP-filter covers are very tight during the first filter change. Using a blunt

object (e.g., the handle of a spoon) the EPP-filter cover can be levered.

Fig 4: Recessed grip filter compartment

A

B

Fig 3: Removal of the design filter cover

A