Fotoelektrik Pauly – Light barriers

E_52692 Ref. 2019-29

10/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

The requisite reflector plates on the reverse are available in different sizes. The format to be used

for the reflector is determined by the clearance distance and the resultant triangulation angle.

For clearance distance

reflector area (width x height)

Model

up to 25 m

400 mm x 100 mm

4R100BL(AF)

up to 50 m

900 mm x 200 mm

18R100BL(AF)

The reflector comprises a carrier plate with individually mounted reflector elements on it. The

reflector elements are fastened with screw connections that cannot be loosened with conventional

tools. Moreover, due to their design, the reflector elements cannot get be misplaced. The special

design of the reflector plate means that the reflector elements are protected against strong

pollution deposits and overflowing water. It is not possible to dismantle the reflector using

conventional tools without damaging it.

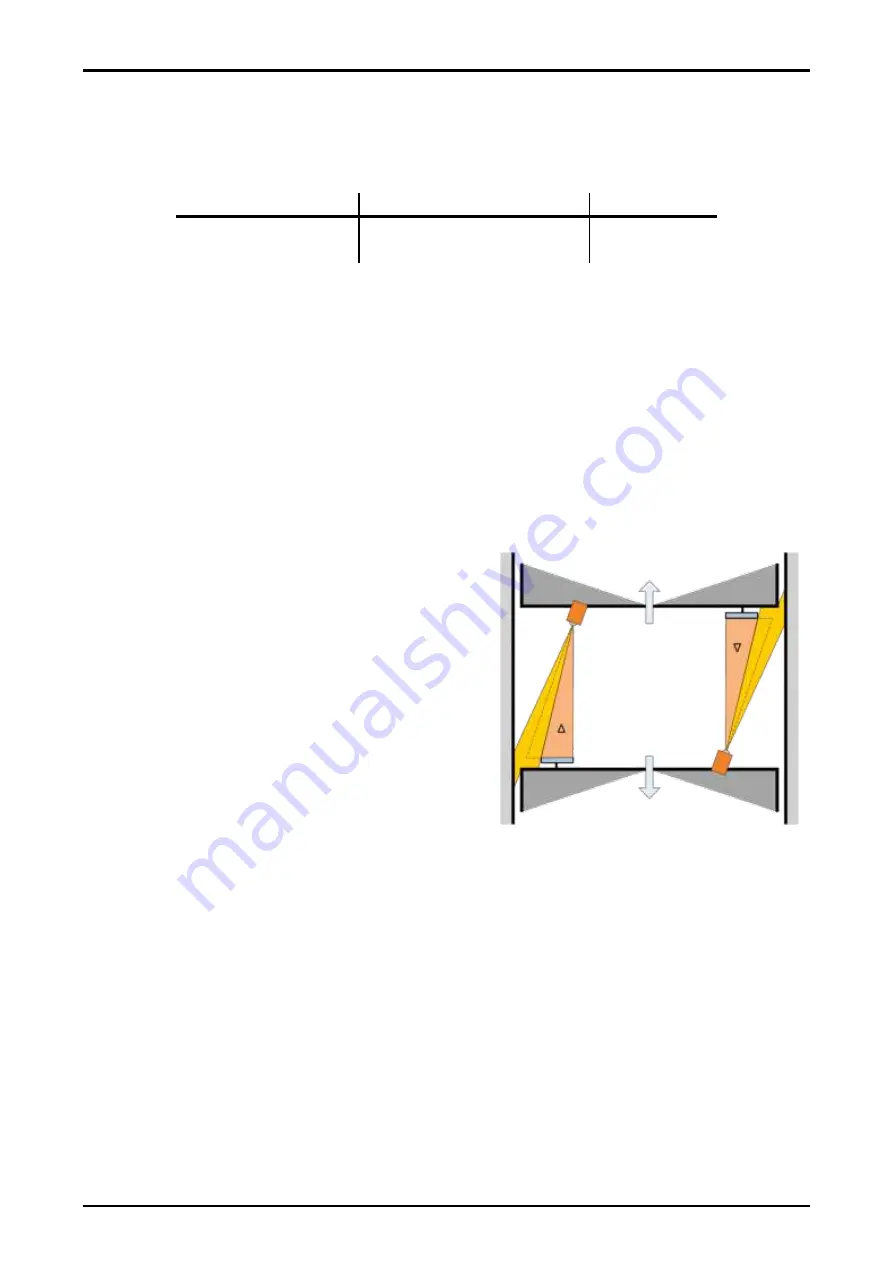

4.3 Description of function

4.3.1 Triangulation triangle

The clearance distance is determined using the

triangulation method. For this purpose, the high

performance reflex light barrier must be aligned at an

angle to the direction of movement of the crane

towards the reflector affixed to the other crane. The

right-angled triangulation triangle is formed as

follows:

(when sighted from the light barrier)

from the distance between the two cranes

–

connecting line between the installation location

of the light barrier and the left reflector

edge = adjacent side to angle >

< and

from the width of the reflector = opposite leg to

the angle >

< and

from the outer light cone form the reflex light

barrier = hypotenuse of the right-angled triangle.

Fig.: 4.3.1

Triangulation triangle

Reflex-light barrier

Crane 2

Crane 1

Reflector