Fotoelektrik Pauly – Light barriers

E_52692 Ref. 2019-29

15/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4.5 Assembly

4.5.1 Horizontal arrangement of the triangulation triangle

Reflector (

) and light barrier-CPV1038 (

)

are mounted horizontally. The triangulation

triangle (

) then lies in the space horizontally.

is mounted onto the crane using the JF57S

adjustment flange. An imaginary line (

) that

runs parallel to the crane track (

) connects

on the right edge of the reflector (

). The

angle (

) of the triangulation triangle should

be selected such that the

is pointing

towards the left reflector edge when the limit

distance is reached (

) (see also chapter on

“adjustment”).

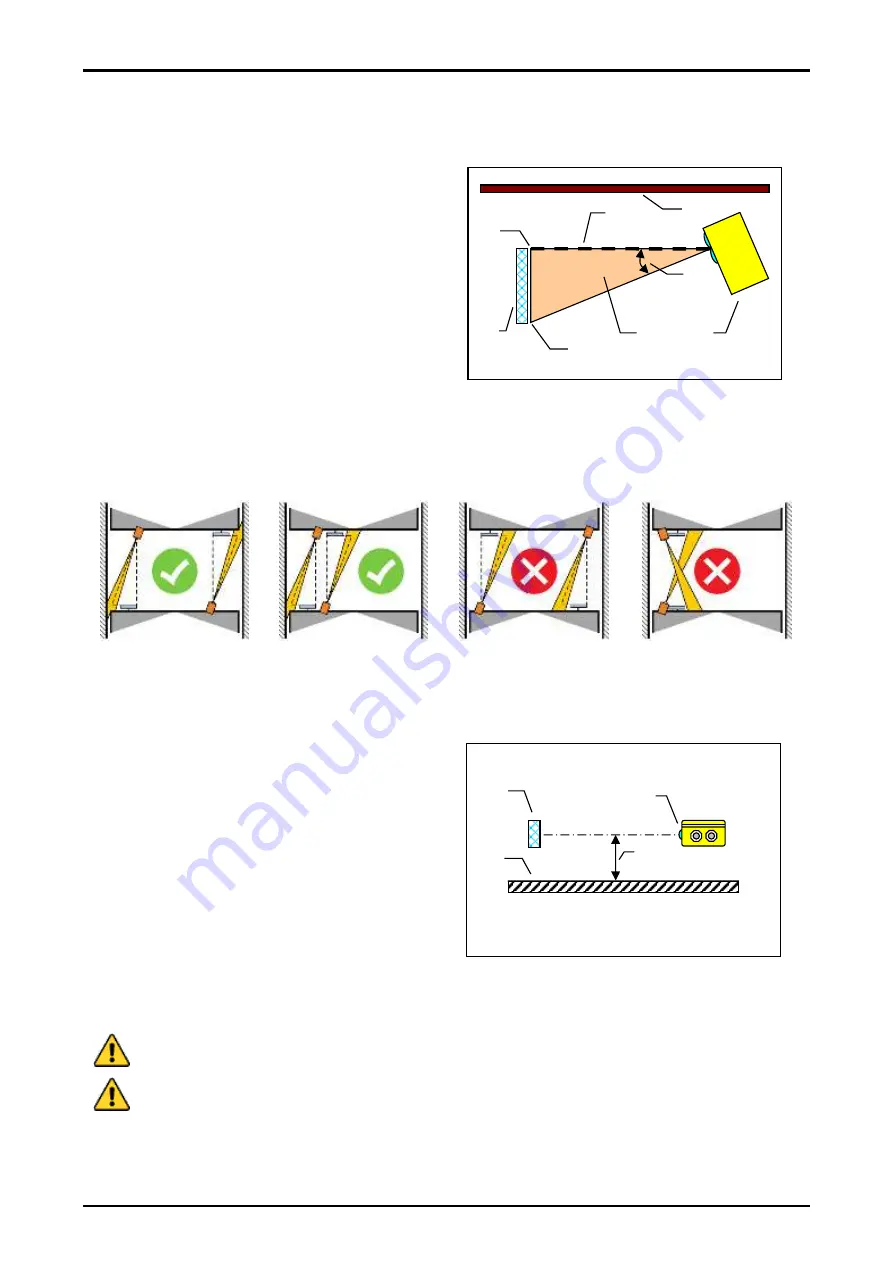

The triangulation triangles must be designed in such a way that the light barrier optics do not

look into each other, directly or via reflections. Examples:

Fig.: 4.5.1-2:

Proper arrangement

Fig.: 4.5.1-3:

Proper arrangement

Fig.: 4.5.1-4:

Wrong arrangement

Fig.: 4.5.1-5:

Wrong arrangement

Note to fig. 4.5 1-3: The distance between the applied outer edge of the device and the reflector

must be at least 200mm.

The Reflector and CPV1038 must be mounted

at the same height. This means that the

middle of the reflector (

) must be positioned

at the same height (

) as the middle of the

lens system of CPV1038 (

). The height of

both parts should be taken from a common

reference point (

).

It is essential to ensure that both optical systems can still view the reflector when both

cranes have been moved together up to buffer distance!

Mount the reflector close to the edge of the crane bridge. Avoid blocking the visible area

of the reflector.

Fig.: 4.5.1-1: Example of a triangulation triangle

clamped to the left

Fig.: 4.5.1-6