Fotoelektrik Pauly – Light barriers

E_52692 Ref. 2019-29

9/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

4. Operating instructions

4.1 Information on this technical description

These operating instructions contain information on the correct use of the CPV1038 distance

monitoring system. They constitute an integral part in the scope of supply.

4.2 Device description

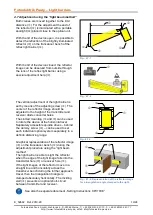

A distance monitoring system or collision protection system consists of a reflex light barrier and a

reflector. The CPV1038 distancing system sets two definite clearance distances separately from

each other. Each individual clearance distance is set in accordance with the triangulation principle.

The electronics for the reflex light barrier system are housed in an enclosure with IP 65 protection.

A protection roof protects the lens system of the reflex light barrier against external conditions, for

example rain, snow or dust. The protection roof is fixed on the enclosure lid. For opening the lid,

the protection roof can be folded up.

An adjustment flange is available for mounting the reflex light barrier. This enables fast and

accurate assembly and alignment.

There are two optical systems in the enclosure. The two optical systems can be set to different

clearance distances independently of each other. Each individual clearance is set by means of a

system-specific spindle axle.

Each system is assigned its own external test unit. The external test units generate continually

defined light signals (infra-red light), which impact on the internal receiving unit through the

receiving lens. The external test units continuously simulate the light reflected by a reflector.

A highly dynamic signal processing procedure evaluates the rays of light pulses received. This

evaluation means that the distance monitoring system is fail-safe, shock resistant, resistant to

external light and stable.

When the set clearance distance is reached, the reflector on the opposite crane can be viewed.

The view of the reflector and any internal component faults decisively alter the dynamic signal

processing and accordingly slow down or stop the

crane’s movement. When farther clearance

distance is reached, the crane’s speed is slowed down. Once the nearer clearance distance is

reached, the crane completely stops (

safe state).

Each system of the reflex light barrier continuously performs tests on its function using the highly

dynamic signal processing procedure

– “continually self-testing”. Any worsening in visibility

conditions or direct pollution of the lenses leads to weakening of the signal. Significantly weakened

signals that could substantially impair the function are detected at an early stage and directly lead

to the stopping of the crane (

safe state).

The high optical performance of the system means the distance monitoring system can be used for

distances up to 50 m and still have very considerable reserves in terms of function.

Travel movement can be halted if

the light barrier is made “blind” due to the lens being covered

over at close range

– “sabotage protection”.

The integrated signal-emitting pollution evaluation is effective for the current reflector view and

evaluates the current signal level. If the signal level on the active reflector view is too low the

pollution is displayed via a signalling contact.