Fotoelektrik Pauly – Light barriers

E_52692 Ref. 2019-29

6/24

Fotoelektrik Pauly GmbH, Wahrbrink 6, D-59368 Werne, T: +49 2389/402 27-70, F: +49 2389/402 27-77

http://www.fotoelektrik-pauly.de, eMail: info@fotoelektrik-pauly.de

2.4 Safety information

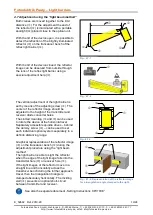

System-related movement tolerances of crane system components and the possible

associated effects on the switching behaviour of the distance monitoring system

must be taken into consideration when planning crane systems.

A correct assembly and alignment of the system are essential for the correct

operation of the system’s safety function.

The set clearance distance could be reduced, e.g. by fog, steam or smoke.

During limited vision, e.g. caused by fog, steam or smoke, the function of the

distance monitoring system must be checked by moving the cranes together.

The light beam on the system must not be interrupted, for example by obstructions

or suspended objects. It is essential that proper attention is paid to this during

assembly and operation of the system.

Before commencement of

work, the system’s safety function must be checked by

moving the cranes together (daily functional check).

The installation of the light barriers may only be performed by authorized technical

personnel who have the requisite professional expertise to install electrical devices on

crane systems.

The device must be immediately taken out of operation in the event of damage or leaks in

the housing, cable or line entries.

Requirements resulting from provisions relating to cranes must be applied under all

circumstances.

All different components with safety functions must be taken into account of the safety

parameters (PL, PFH

d

, MTTF

d

), e.g. an optionally required additional external power supply

or output side follow-up circuit.

Further or supplementary protective measures may be required on the basis of risk

assessments for special areas of application, e.g. restart inhibit. According to

EN ISO 13849, an automatic restart may only take place, if no hazardous situation exists.

The distancing system may not be bridged.

The crane operator and/or the crane manufacturer must be aware and comply to the

information that applies to his area of deployment; this also applies to the product, cables

and lines installation

If condensation on the reflector surface cannot be excluded for an application with high air

humidity or/and abrupt change in temperature then an anti-fogging coated reflector version

must be used. A suitable reflector type will be model 4R100BLAF or model 18R100BLAF

(see catalog of applicable documents in section 4.9).

If the device is operated in conjunction with other components such as control systems or

sensors, the corresponding user instructions must be heeded.