3 Product description

2015/03

9936052x-mub-en – V09

9

Change of the flow line [specialist]

Dismounting the mixing valve

1.

Take off the thermometer handles (A-2, F-2) and remove the insulating front shell.

2.

Take the HeatBloC out of the insulating back shell.

3.

Dismount the mixing valve (C).

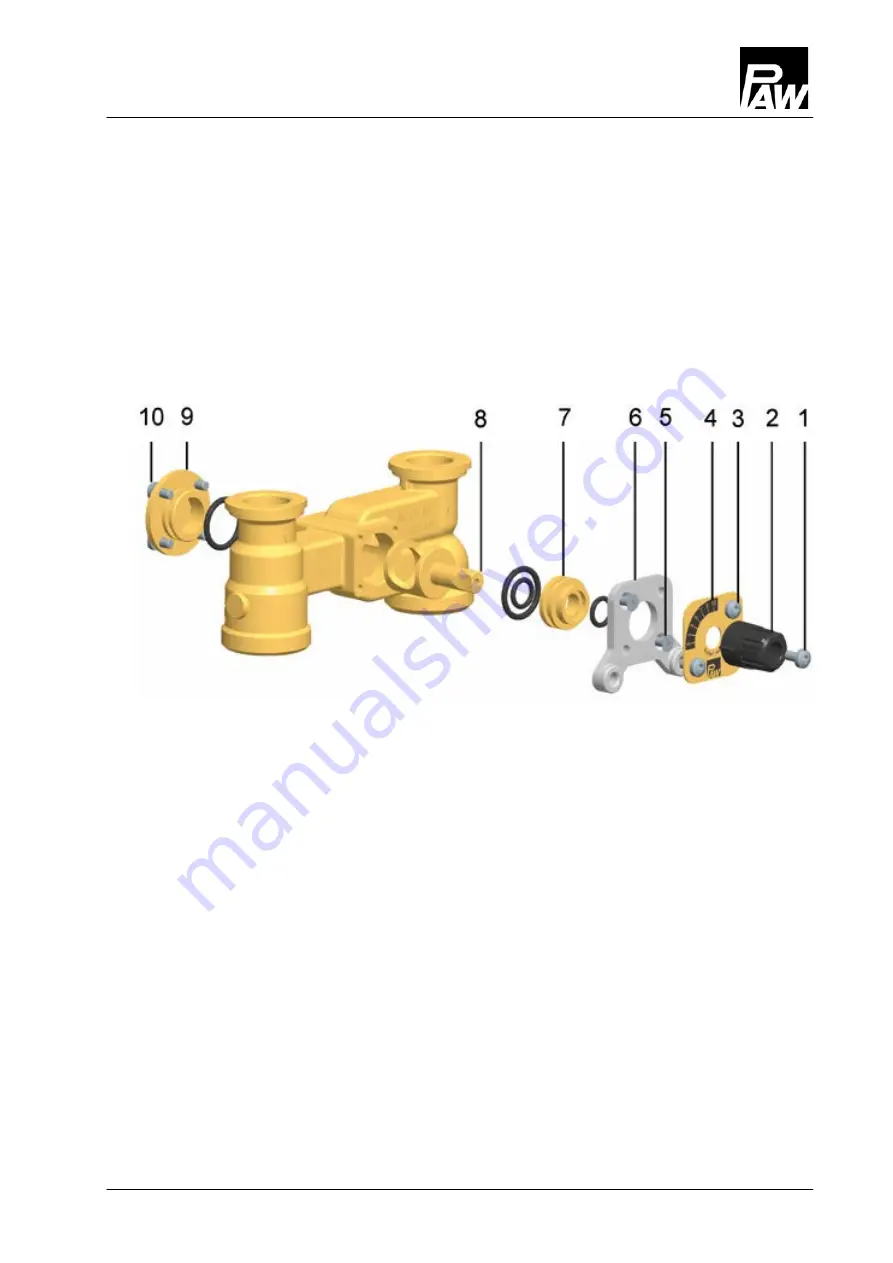

Conversion of the mixing valve

1.

Unscrew the screw (1).

2.

Take the rotary knob (2) off the rod of the cock.

3.

Unscrew the screw (3).

4.

Take off the cover plate (4).

5.

Unscrew the two screws (5).

6.

Remove the front plate (6).

7.

Extract the sealing bush (7) and the valve cock (8) from the mixing valve body.

8.

Unscrew the screws (10) on the rear side of the mixing valve.

9.

Take off the cover (9) on the rear side and fix it at the other side of the mixing valve

using the screws (10).

10.

Insert the sealing bush (7) and the valve cock (8) into the channel of the mixing valve.

11.

Fix the front cover (6) with the screws (5).